Hydrostatic axial piston engine with inclined axes

A technology of axial piston engine and hydrostatic pressure applied to reciprocating piston engines, variable displacement engines, liquid fuel engines, etc., which can solve the problems of increasing manufacturing costs and component consumption, and achieve small loss, reduce structural consumption and Space requirements, effect of reducing axial structural space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

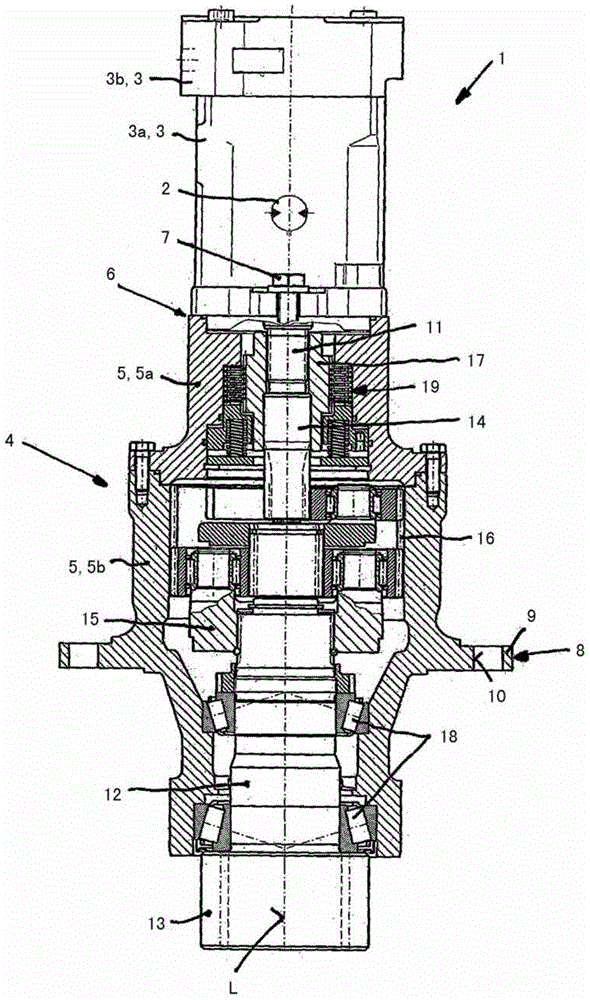

[0040] FIG. 1 shows a prior art hydrostatic drive 1 , which is designed, for example, as a rotary drive.

[0041] The drive device 1 comprises a hydrostatic axial piston machine 2 of inclined-axis design, arranged in a housing 3 and designed as a hydraulic motor, which drives a downstream reduction gear 4 , The reduction gear is arranged in the gear housing 5 . In the exemplary embodiment shown, the transmission housing 5 is designed in two parts and is formed by an upper housing part 5 a and a lower housing part 5 b , which are flanged to one another. The housing 3 of the axial piston machine 2 is fastened to the transmission housing 5 by means of fastening flanges 6 and corresponding fastening screws 7 . The housing 3 of the axial piston machine comprises a housing cylinder 3 a and a housing cover 3 b flanged to the housing cylinder 3 a, on which the hydraulic connections of the axial piston machine 2 are formed. The oblique axial piston machine 2 and the downstream reduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com