An integrated rocker arm for engine braking

An engine braking, integrated technology, applied in the field of integrated rocker arms, can solve the problems of increasing system complexity, high manufacturing and assembly costs, and achieve improved sensitivity and reliability, shortened oil circuit stroke, and convenient installation and adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

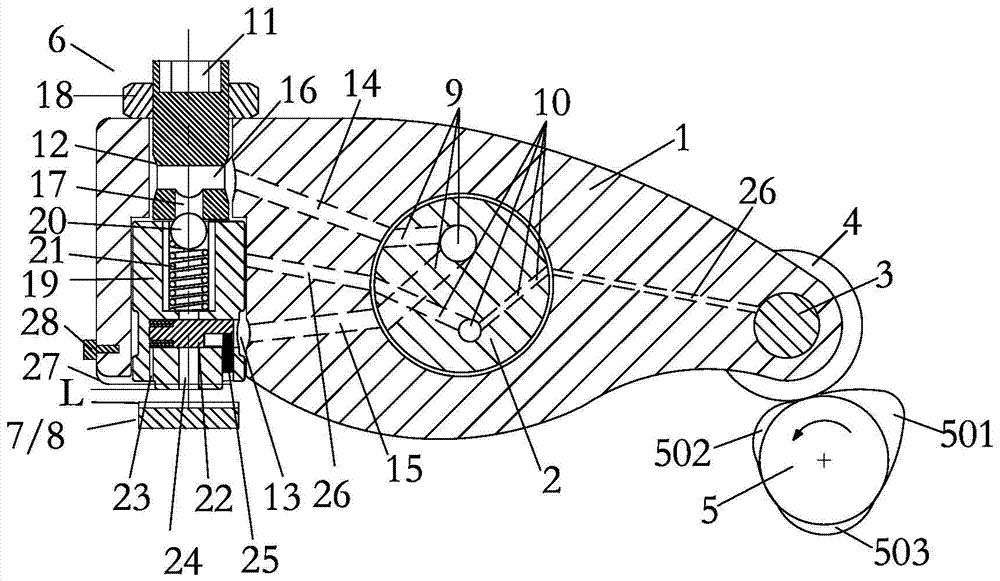

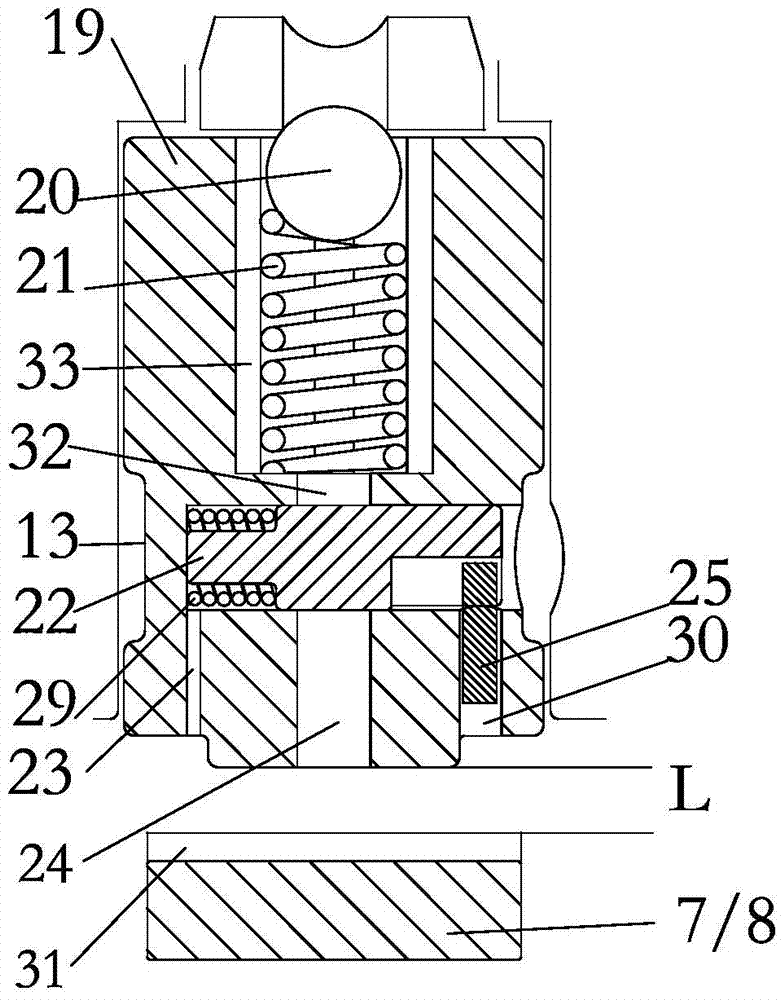

[0038] Example 1: see figure 1 -2:

[0039] An integrated rocker arm for generating engine braking. The rocker arm 1 is arranged on the rocker arm shaft 2. One end of the rocker arm 1 is provided with a roller 4 through a pin 3. The roller 4 is in contact with the exhaust cam 5. The air cam 5 is provided with a normal exhaust protrusion 501, a compression release brake protrusion 502 and a brake recirculation protrusion 503, and a brake mechanism 6 is arranged at the other end of the rocker arm 1, and the brake mechanism 6 It includes a brake adjusting bolt 11 and a brake piston arranged at the lower part of the brake adjusting bolt 11, an exhaust valve bridge 7 or a single exhaust valve 8 is arranged under the brake piston, and a brake valve is arranged on the rocker shaft 2. The oil passage 9 and the lubricating oil passage 10 are provided with a first lubricating oil passage 26 connecting the pin 3 and the middle part of the brake piston 19 on the rocker arm 1 .

[0040] ...

Embodiment 2

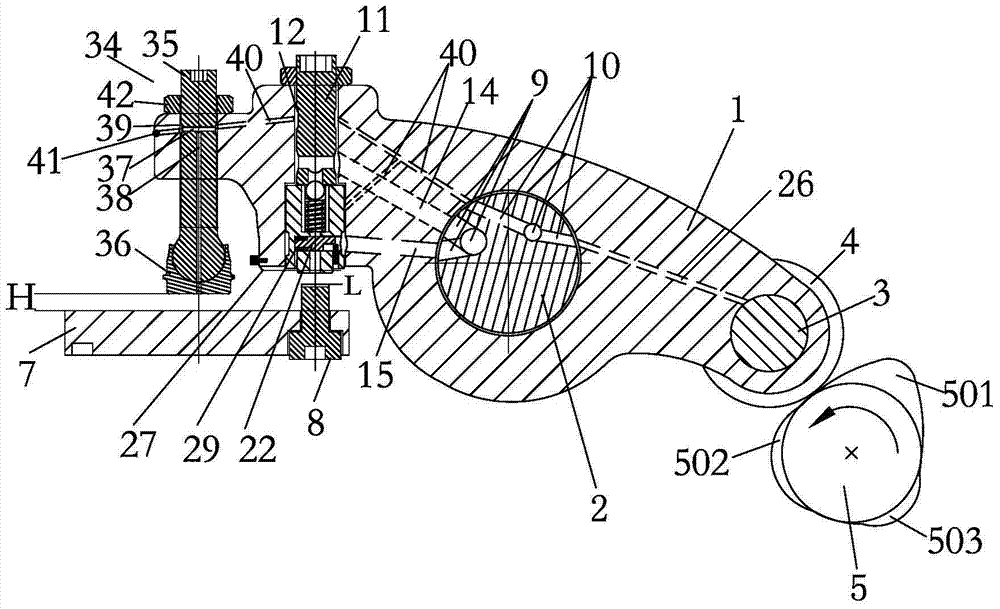

[0051] Example 2: see image 3 :

[0052] The structure of this embodiment and embodiment 1 is basically the same, and its difference is:

[0053] On the basis of the structure of Embodiment 1, an adjustment screw assembly 34 for operating the exhaust valve bridge exhaust is added on the rocker arm 1 outside the braking mechanism, and the braking mechanism 7 of this embodiment is used to open the single exhaust valve 8.

[0054] The adjusting screw assembly 34 includes an exhaust adjusting screw 35 and a socket 36 arranged below the exhaust adjusting screw 35. The adjusting screw 35 is fixed on the rocker arm 1 by a nut 42, and a diameter is provided on the upper end of the exhaust adjusting screw 35. To the oil passage 37, and from the radial oil passage 37 down and through the radial oil passage 37 of the socket 36, the radial oil passage 37 of the exhaust adjustment screw 35 is also provided with a third annular oil groove 39 , the rocker arm 1 is provided with a second ...

Embodiment 3

[0060] Embodiment 3: see Figure 4 :

[0061] The difference between this embodiment and Embodiment 2 lies in the difference in the structure of the adjusting screw assembly 34 .

[0062]The adjusting screw assembly 34 includes an exhaust adjusting screw 35 and a socket 36 arranged below the exhaust adjusting screw 35. The exhaust adjusting screw 35 is fixed on the rocker arm by a nut 42, and the upper end of the exhaust adjusting screw 35 A radial oil passage 37 is provided, and an axial oil passage 38 runs downwards from the radial oil passage 37 and passes through the socket 36, and the exhaust adjustment screw 35 is also provided with a third annular oil groove at the radial oil passage 37 39. A second lubricating oil passage 40 is provided on the rocker arm, and the second lubricating oil passage 40 communicates with the lubricating oil passage on the rocker shaft, and the outer end of the second lubricating oil passage 40 communicates with the outside world. 41 is bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com