Preparation method of metal tungsten thin film

A metal tungsten and thin film technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the micro-deformation of the whole wafer, affect the transmission of visible light or isolate the quantity and quality, and affect the imaging quality of CIS products and other problems to achieve the effect of stress reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

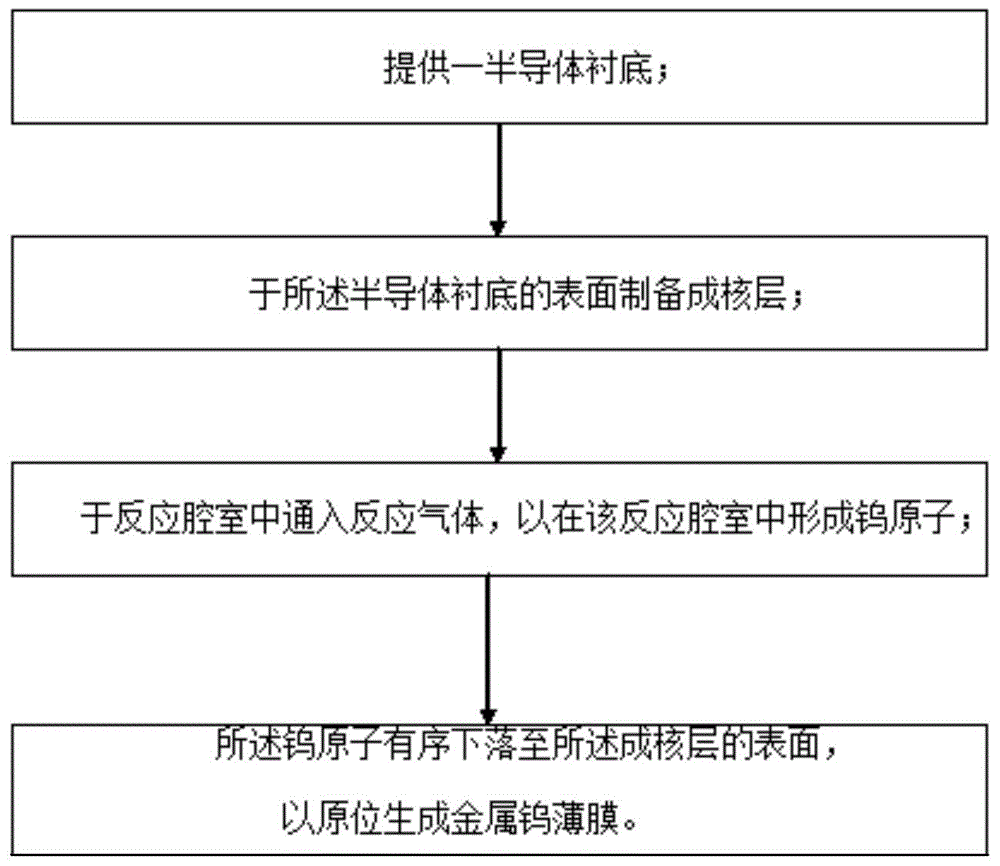

[0022] see figure 1 As shown in the structure, this embodiment provides a method for preparing an ultra-low stress metal tungsten film. The stress of the metal tungsten film is lower than that of a conventional metal tungsten film, forming an ultra-low stress metal tungsten film. Increase the reaction temperature in the reaction chamber and reduce the amount of reaction gas at the same time, thereby increasing tungsten hexafluoride (WF6) and hydrogen (H2) to generate metal tungsten atoms in the reaction chamber. The method specifically includes the following steps:

[0023] Firstly, a semiconductor substrate is provided, preferably, the material of the semiconductor substrate is titanium nitride. Continue to prepare a nucleation layer on the surface of the semiconductor substrate.

[0024] As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com