Floating production platform

A floating production and platform technology, applied in the direction of floating buildings, etc., can solve the problems of increased drilling operation risk, difficult to control heave performance, large hull waterline area, etc., and achieves improved motion performance, low cost, and simple construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

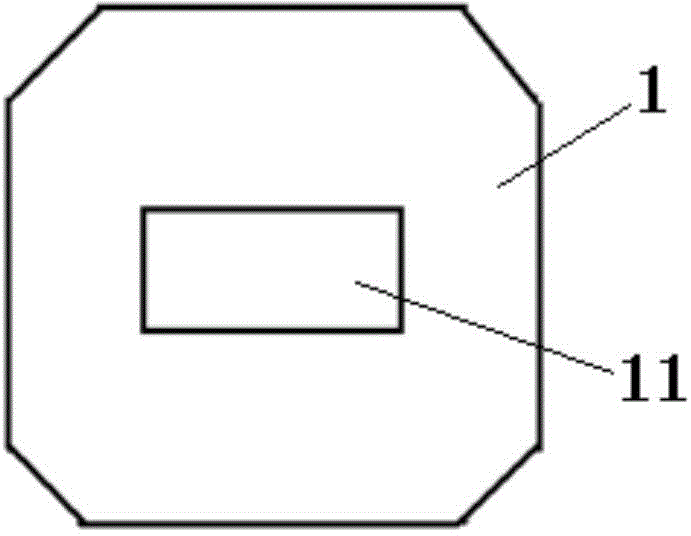

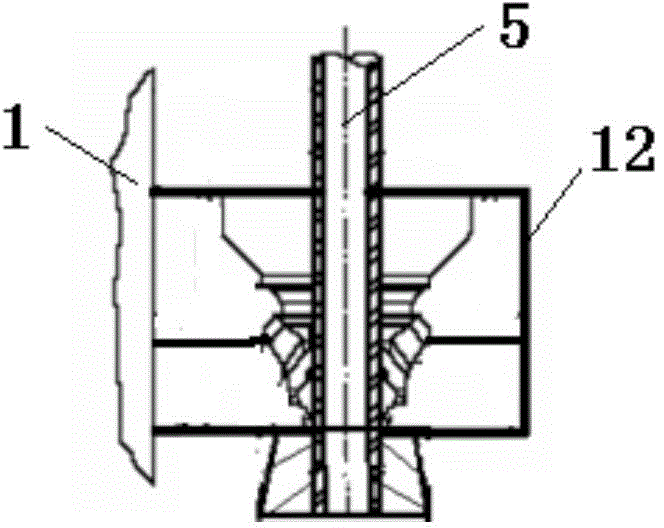

[0020] Such as figure 1 , figure 2 As shown, the present invention includes a floating body 1 in an octagonal prism structure, and an upper deck 2 is fastened to the top of the floating body 1 . An oil and gas processing unit 3 and a drilling unit 4 are arranged on the upper deck 2 . Along the axial direction of the buoyant body 1, there is a moon pool 11 that penetrates up and down and is used for drilling operations. On the outer wall surface of the lower part of the floating body 1, a plurality of suspension supports 12 are evenly fastened and connected at intervals in the circumferential direction, and each suspension support 12 is hinged with one end of a group of vertically downwardly arranged steel pipes 5 by a hinge mechanism (such as image 3 shown), the other end of each group of steel pipes 5 is hinged with a suspension support 61 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com