Three-layer cascade ring packing

A step ring and step technology, applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as nesting, reducing product quality, affecting production efficiency, etc., to prevent nesting stacking, strengthening the strength of the outer wall, and reducing the effect of passing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

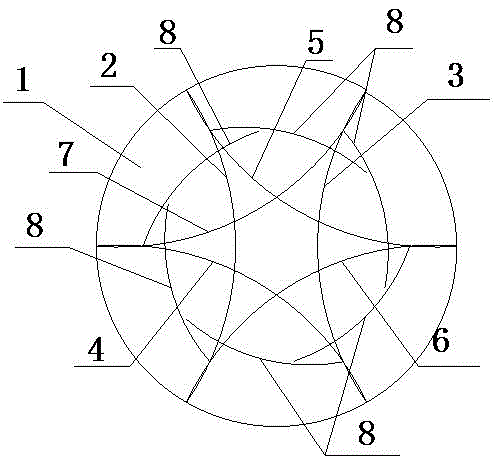

[0013] The three-layer stepped ring packing provided by this embodiment, such as figure 1 As shown, the filler is made of metal, and its outer wall 1 is circular in plan view, and the inner wall circumference of the outer wall 1 is formed with first to sixth blades. Wherein, the first blade 2 is located between two points of an arc at intervals of 120 degrees; the second blade 3 and the first blade 2 are symmetrical to the center of the inner wall circumference of the outer wall 1; the third blade 4 is located at the center of the first blade 2 Between the two points obtained after the two vertices are rotated counterclockwise on the inner wall circumference of the outer wall 1 by an arc of 60 degrees, the fourth blade 5 and the third blade 4 are symmetrical to the center of the inner wall circumference of the outer wall 1; the fifth blade 6 is located at Between the two points obtained by rotating the two apexes of the third blade 4 counterclockwise on the inner wall circumfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com