Manufacturing method of glass molded body and manufacturing apparatus of glass molded body

A glass forming and manufacturing method technology, applied in glass forming, glass pressing, glass manufacturing equipment and other directions, can solve problems such as poor lens shape, and achieve the effect of suppressing uneven temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings.

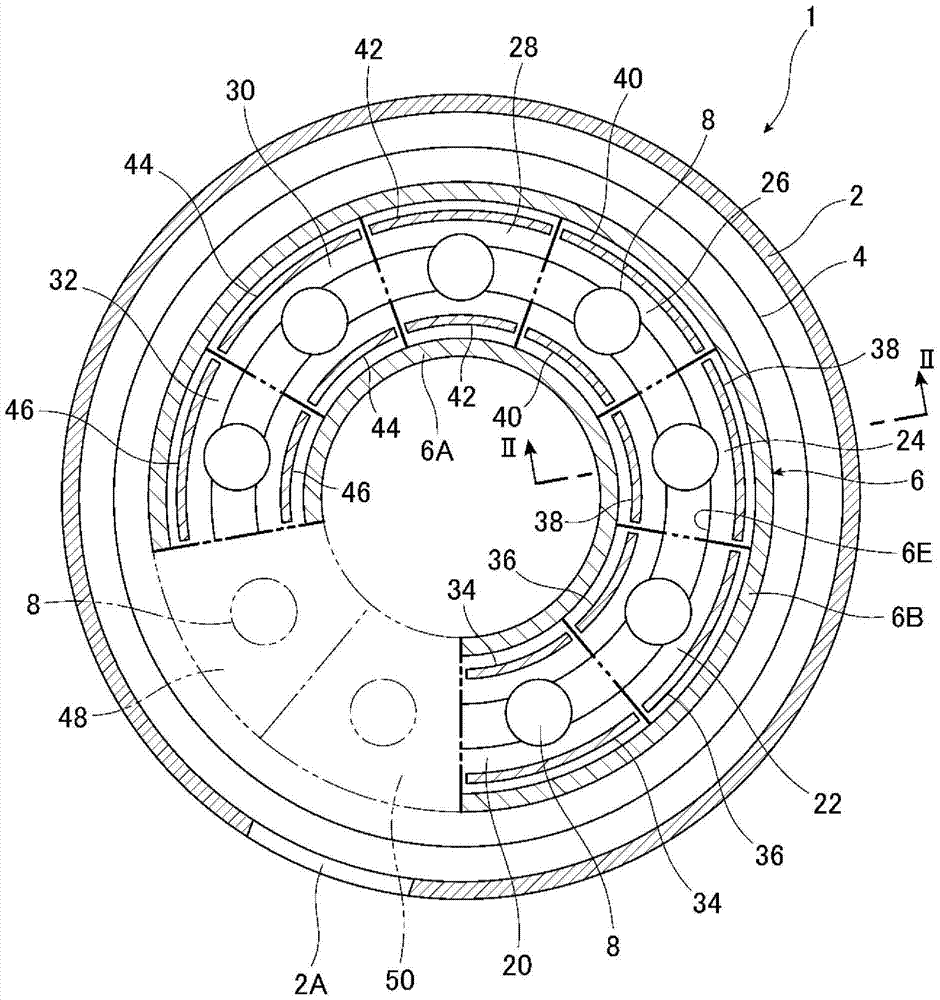

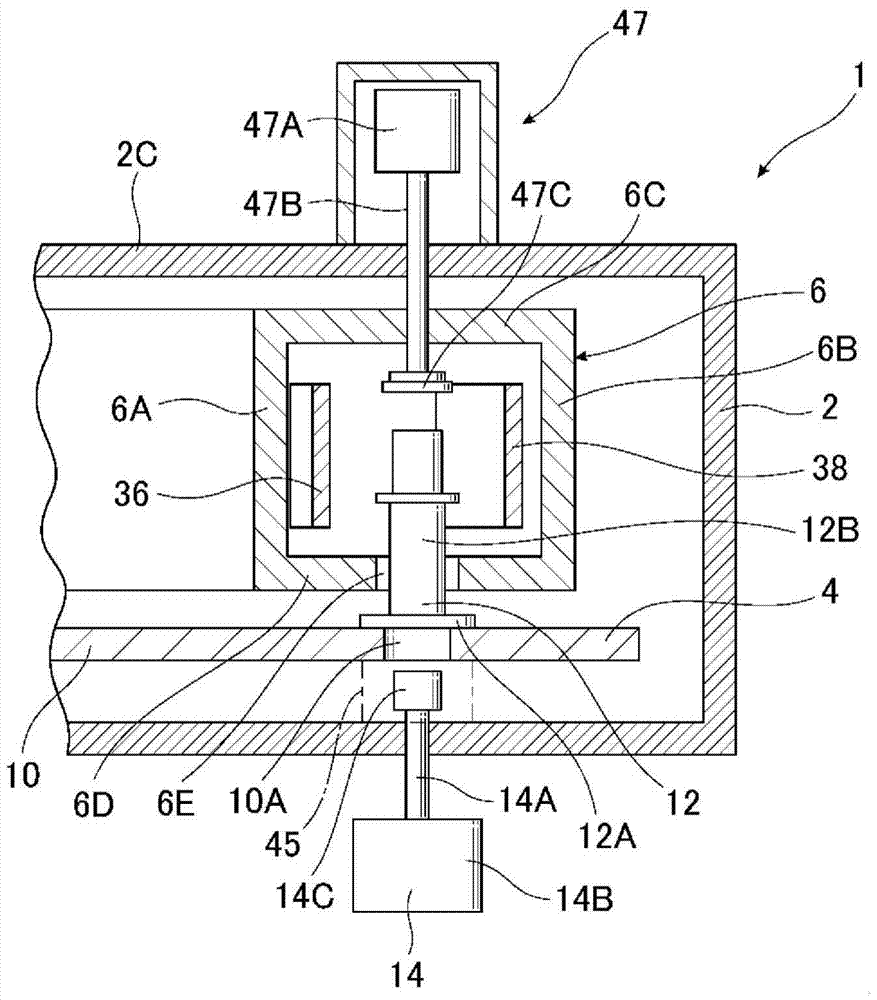

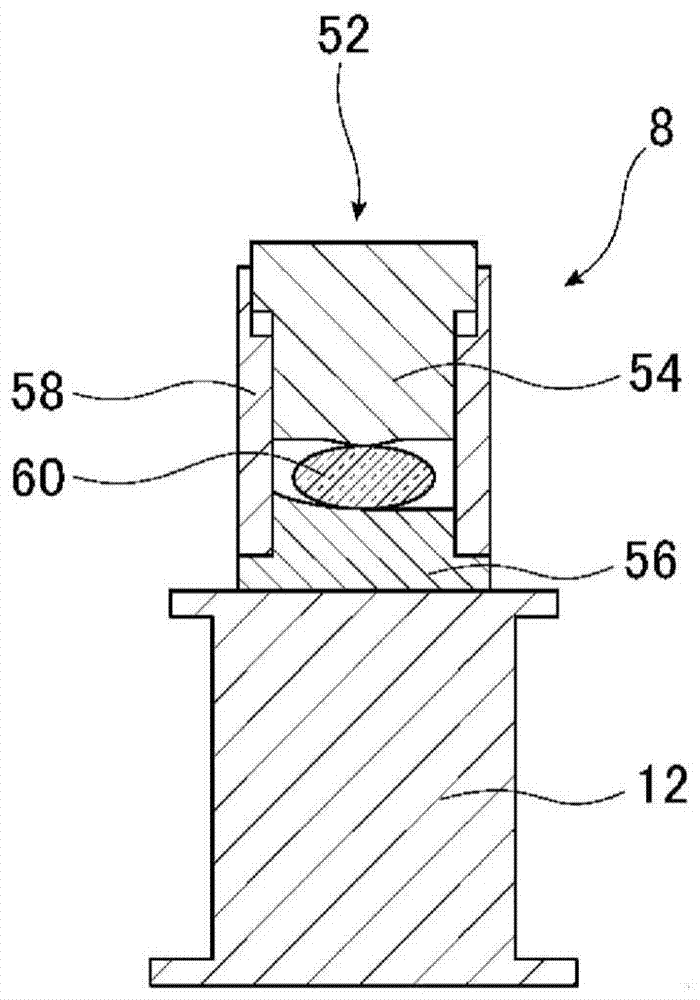

[0028] figure 1 It is a horizontal sectional view showing the structure of the manufacturing apparatus of the glass molded body of this embodiment, figure 2 yes figure 1 A sectional view along line II-II, image 3 is a vertical sectional view of the mold unit.

[0029] Such as figure 1 and figure 2 As shown, the manufacturing apparatus 1 of the glass molded object of this embodiment has: the outer casing 2, which is formed in a substantially cylindrical shape; the turntable 4, which is installed in the outer casing 2; Above the turntable 4 in the casing 2, the horizontal section is arc-shaped. The outer casing 2, the inner casing 6 and the turntable 4 are arranged coaxially.

[0030] The outer casing 2 defines a substantially cylindrical space inside, and has an opening 2A for carrying in and out the die unit 8 in a part of the side surface....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com