Plug electrical connector

A technology for electrical connectors and plugs, applied in the direction of connection, welding/welding connection, circuit, etc., can solve the problems of skewed welding feet and difficult welding operations, and achieve the effect of reducing the gap distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

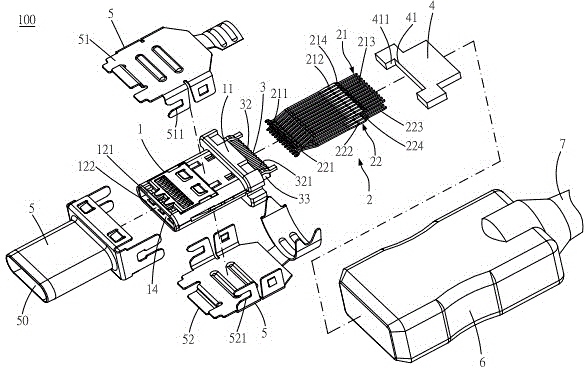

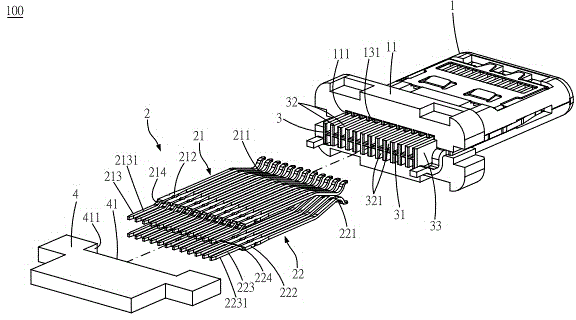

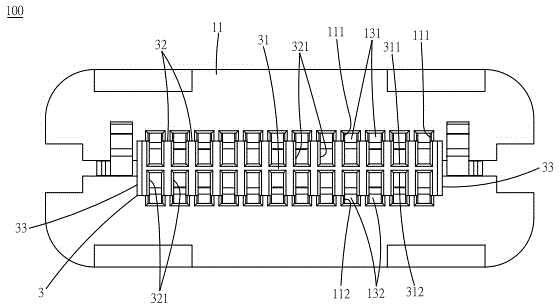

[0060] figure 1 It is an exploded schematic view of the electrical plug connector of the present invention, figure 2 It is a partially exploded schematic diagram (1) of the electrical plug connector of the present invention, Figure 3A It is a schematic diagram of the rear view of the insulating body of the present invention, Figure 3B It is a top view cross-sectional schematic view of the insulating body of the present invention, Figure 4 It is a partially exploded schematic diagram (2) of the electrical plug connector of the present invention. refer to figure 1 , figure 2 , Figure 3A , Figure 3B and Figure 4 , is an embodiment of the electrical plug connector 100 of the present invention. In this embodiment, the electrical plug connector 100 is a micro-USB (Type-C) connection interface specification, which can conform to the transmission of USB3.0 signals or USB2.0 signals. The electrical plug connector 100 includes an insulating body 1 , a terminal set 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com