High current resistance vehicle power off switch

A power-off switch, high-current technology, applied in electrical switches, circuits, electrical components, etc., can solve problems such as inability to withstand large currents, and achieve the effects of improving current resistance, good structural strength, and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

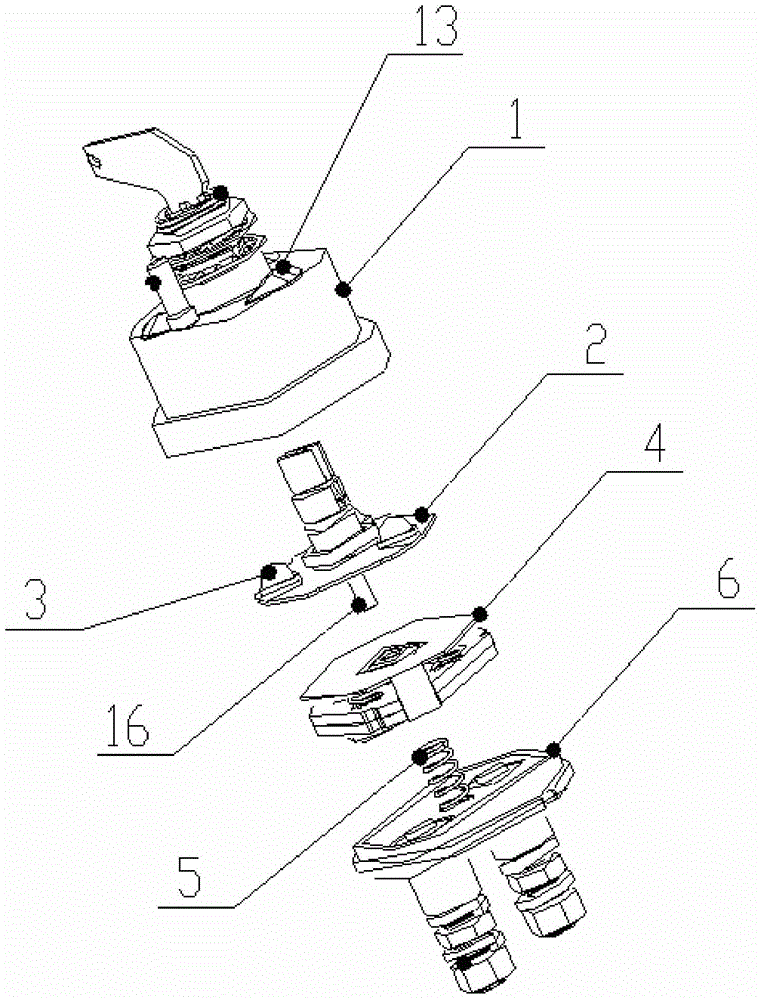

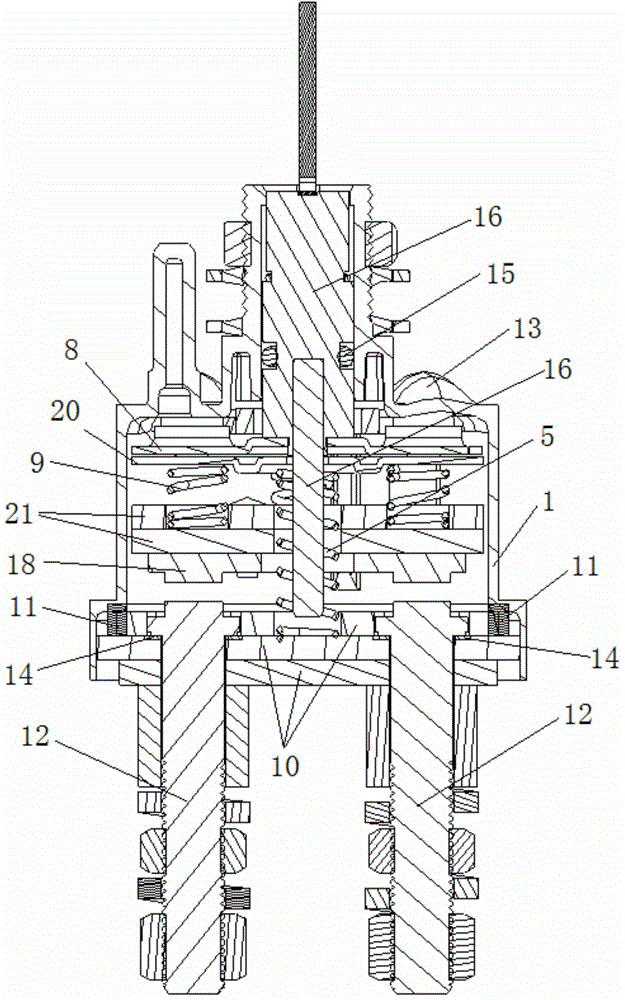

[0014] Examples such as Figures 1 to 5 As shown, a large current-resistant vehicle power-off switch includes a housing 1, a movable contact assembly 4 and a static contact assembly 6 arranged in the housing 1; The shaft assembly 2.

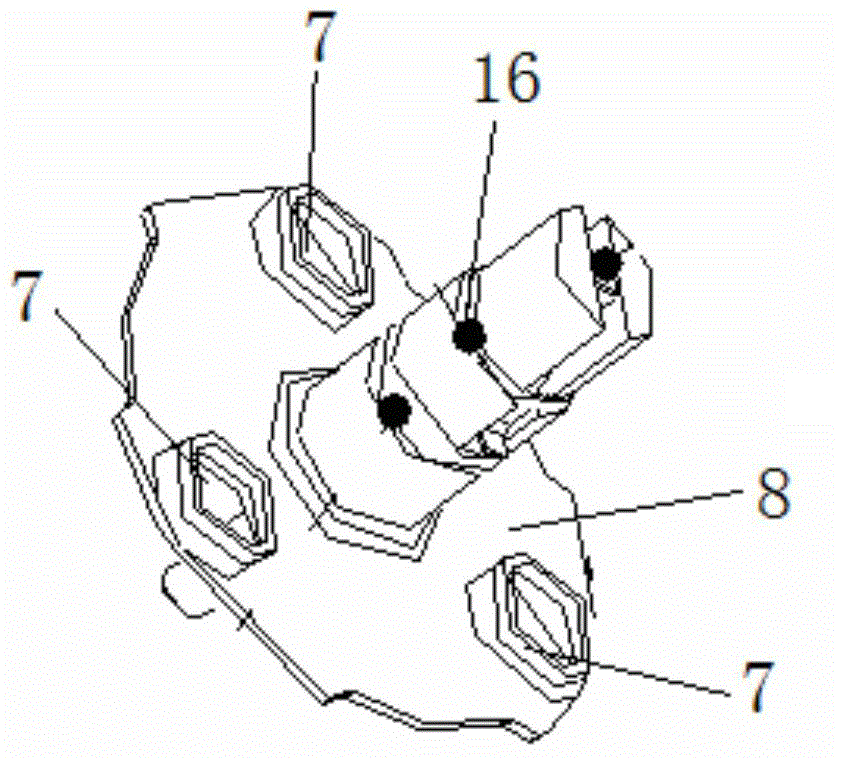

[0015] Specifically, the rotating shaft assembly 2 includes a rotating shaft 16, one end of the rotating shaft 16 protrudes from the housing 1, and a structure such as a rotating slot or a protruding piece is provided at the end, which can facilitate the rotation of the rotating shaft 16 with a key. Matching form. A second sealing ring 15 is arranged between the rotating shaft 16 and the housing 1 to ensure that dust and water will not enter the switch body from between the housing 1 and the rotating shaft 16 to ensure the stability and safety of the switch. The rotating shaft 16 is fixedly provided with a steel ball limiting plate 8 through the expansion riveting process, and a group of steel ball placement holes 7 are arranged on the steel ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com