Drying refrigeration system for air-source heat pump

An air energy heat pump and drying room technology, applied in the direction of drying, drying machine, heating and cooling combination, etc., can solve the problems of waste of resources, environmental impact, and unrecycled air-conditioning, and achieve the effect of saving cooling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

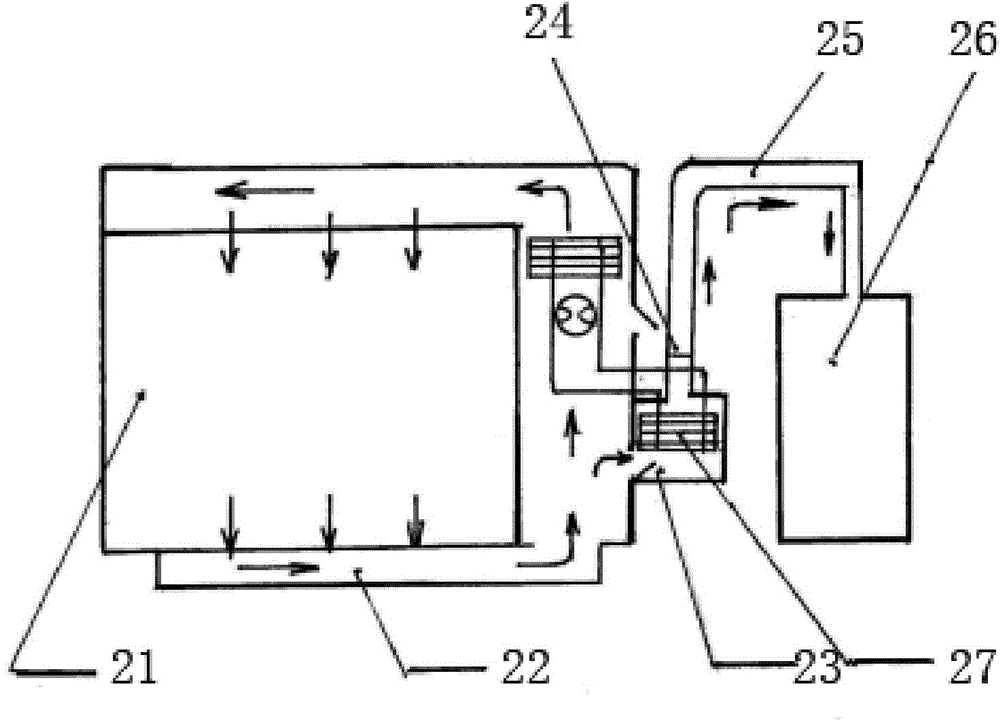

[0011] Such as figure 2 As shown, an air energy heat pump drying and refrigeration system includes a drying room 21, a cold storage room 26, an airtight room 23 and an air energy heat pump 27. The outlet is communicated with a closed room 23 through a connecting pipe, and the evaporator 11 of an air source heat pump 27 is arranged in the closed room 23 , and the cold air outlet 24 of the closed room is communicated with a refrigerating room 26 through a pipe 25 .

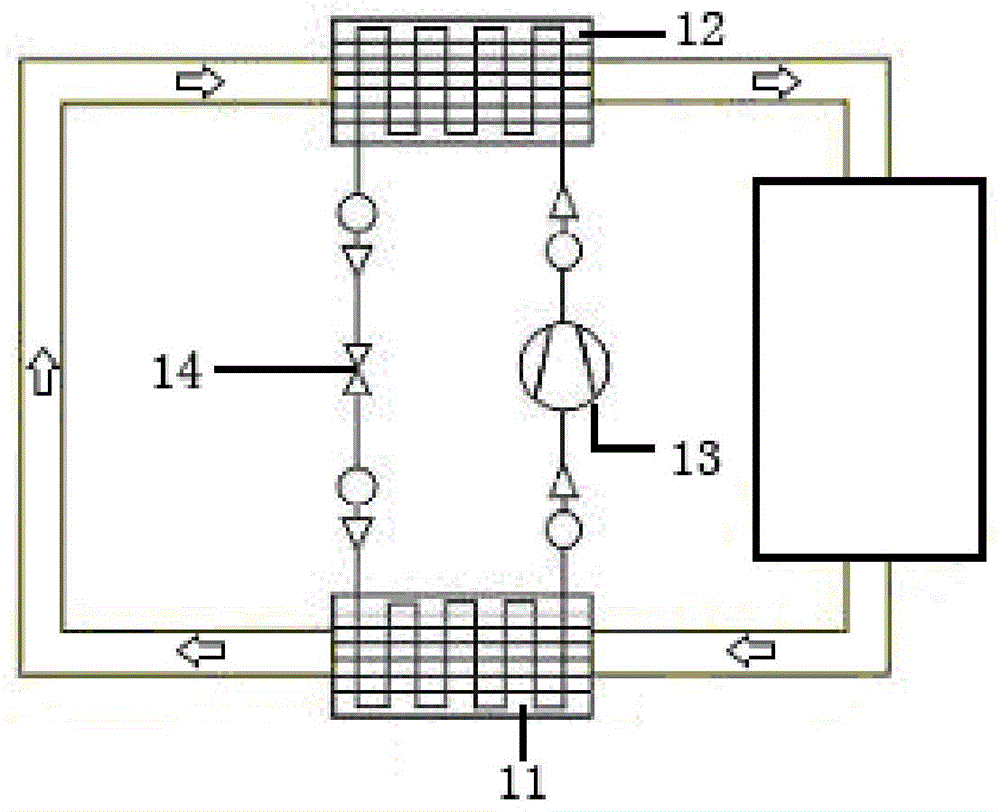

[0012] according to figure 1 It can be seen that the air energy heat pump 27 includes an evaporator 11, a condenser 12, a compressor 13 and an expansion valve 14. By allowing the working medium to continuously complete evaporation (absorb heat from the outdoor environment)→compression→condensation (in the indoor drying room release heat in the middle) → throttling → re-evaporation thermodynamic cycle process, so as to transfer the heat in the external low-temperature environment to the drying room 21, and the refr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com