a turbine

A technology of turbines and axles, which is applied in the direction of gas turbine devices, mechanical equipment, machines/engines, etc., can solve the problems of low energy conversion efficiency, impact on blade service life, large pressure loss and energy loss, etc., to achieve efficient use of fuel energy, The effect of improving efficiency and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

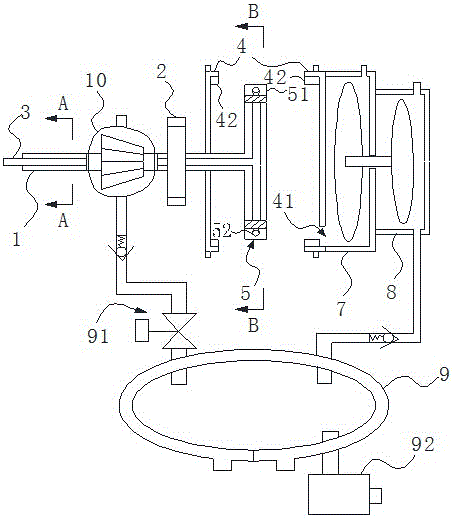

[0050] Such as Figure 1-Figure 5 As shown, a turbine includes a wheel shaft 1, a power output wheel 2, a casing 4 and a wheel disc 5, the wheel disc 5 is arranged inside the casing 4, and the wheel shaft 1 rotatably runs through the casing 4 and the end is fixedly connected to the center of the wheel disc 5, the power output wheel 2 is arranged on the wheel shaft 1 and is used for outputting power;

[0051] The casing 4 and the roulette 5 are cylindrical as a whole;

[0052] The wheel disc 5 is a hollow structure and thereby forms an inner cavity, the wheel shaft 1 is a tubular structure, and the wheel disc 5 and the end of the wheel shaft 1 are connected through and fixed to form a rotor body of the turbine;

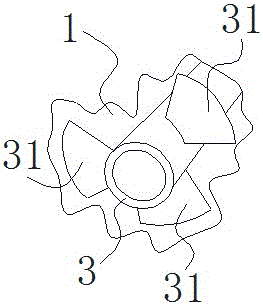

[0053] The outer surface of the wheel disc 5 is evenly provided with a plurality of hollow gear teeth 51 extending along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com