Super-long-workability steel arch self-compacting concrete

A self-compacting concrete and workability technology, applied in the field of concrete, can solve problems such as the loss of concrete workability over time, and achieve the effect of sufficient concrete slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] Table 1 is the specific proportioning of the present embodiment:

[0021] Table 1

[0022] raw material

water

mineral powder

fine aggregate

Coarse aggregate

expansion agent

Admixture

Specification

42.5PO

S95

Middle sand

5-10mm

HEA

Modified polycarboxylate

Unilateral dosage

175

400

170

816

800

57

6.27(1.1%)

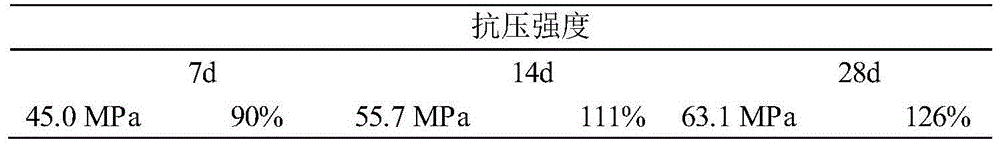

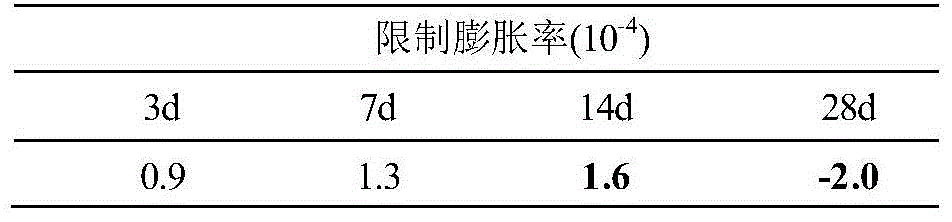

[0023] After testing, the working performance of concrete:

[0024] Workability: Fresh concrete has good workability, no bleeding, no floating ash, and no bleeding after standing still;

[0025] Slump: The initial slump of fresh concrete is 260mm;

[0026] Setting time: the initial setting time is 8 hours, and the final setting time is about 12 hours.

[0027] After testing, concrete self-compacting performance:

[0028] Slump 260-280mm, expansion 760-850mm, T 500 ≤5s, the collapse velocity is ≤5s; the slump expansion is 550-655...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com