Fast steel bar straightener and method for utilizing straightener for straightening steel bars

A straightening machine and steel bar technology, applied in the field of steel bar processing, can solve problems such as low straightening efficiency, poor straightening effect, and adverse effects on the mechanical properties of reserved steel bars, so as to avoid performance damage, simple structure, and strong equipment versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

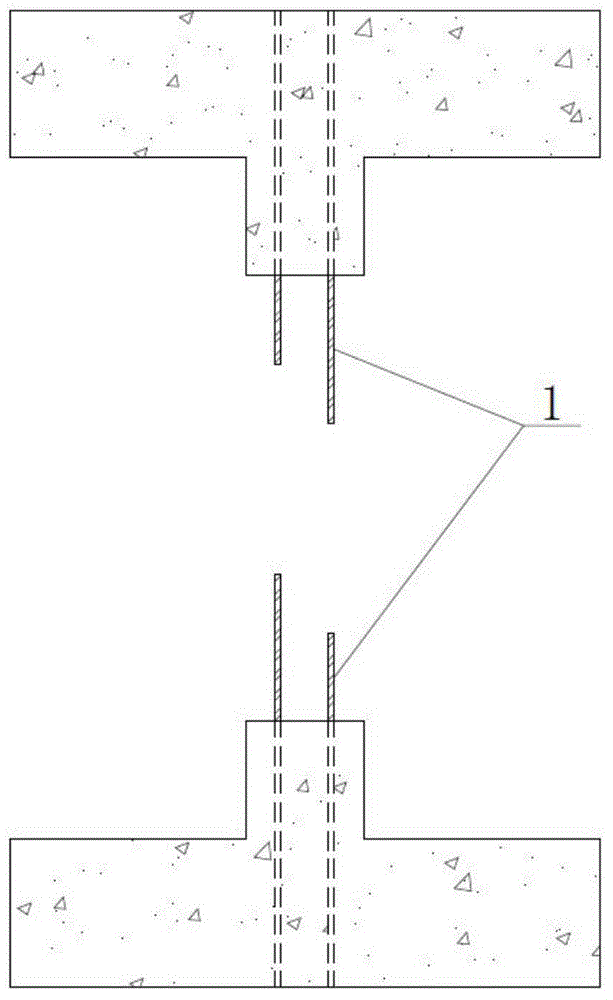

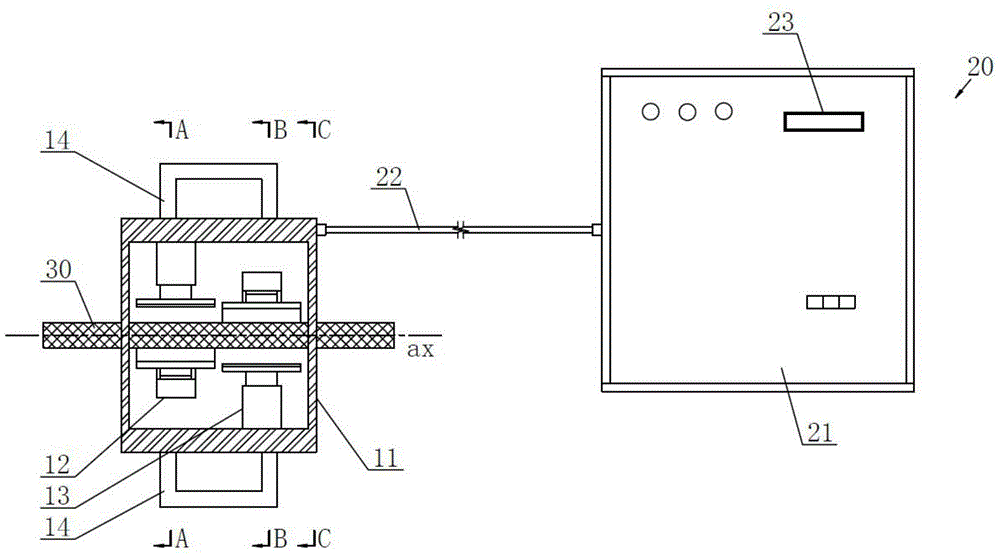

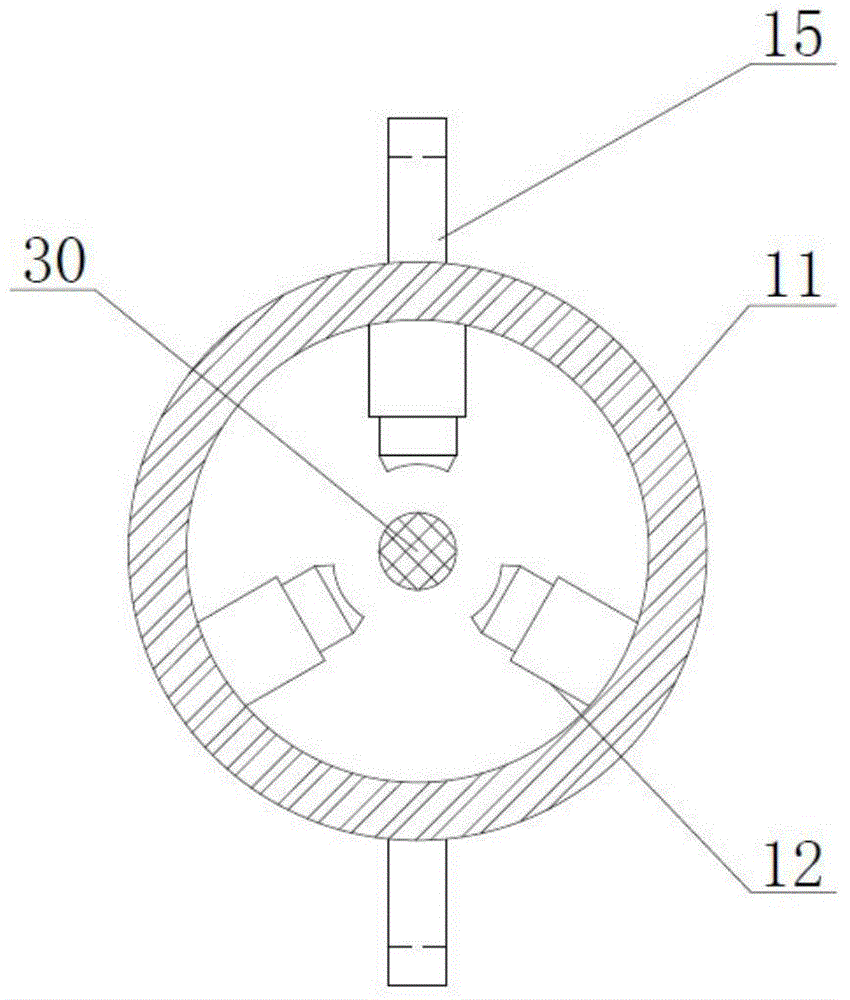

[0028] Example 1: Combining Figure 2 to Figure 6 The steel bar straightening machine of present embodiment is illustrated, as figure 2 As shown, the steel bar quick straightening machine includes a sleeve 11 for straightening reserved steel bars 30, and a hydraulic device 20 communicated with the sleeve 11; the inner wall of the sleeve 11 is provided with at least two sets of hydraulic jack assemblies, namely Hydraulic jack assembly one 12 and hydraulic jack assembly two 13; wherein, each set of hydraulic jack assemblies is provided with three separate hydraulic jacks distributed radially along the axis ax of the sleeve 11 and located on the same section, and each separate hydraulic jack The jacks are all in communication with the hydraulic device 20 , and the separate hydraulic jacks can push in the direction of the axis ax of the sleeve 11 under the action of the hydraulic device 20 , thereby tightening and straightening the reserved steel bar 30 passing through the sleeve...

Embodiment 2

[0036] Embodiment 2: Combination Figure 2 to Figure 6 Illustrate the method for straightening reserved steel bars by using the steel bar quick straightening machine described in embodiment one, and the specific steps are as follows:

[0037] 1. Make the piston rod b of the separate hydraulic jack be at the initial position (that is, the state where the piston rod b is contracted), and the free end of the reserved steel bar 30 penetrates the sleeve 11 along the axis ax and is interposed between the separate hydraulic jacks;

[0038] 2. Turn on the switch located on the handle 14 to start the hydraulic main engine 21, and the top plate c of the separate hydraulic jack pushes toward the reserved steel bar 30 at the same time, so that the reserved steel bar 30 is gradually squeezed and tightened by the top plate c, thereby straightening the The reserved steel bar 30 of this section in the cylinder 11, the reserved steel bar 30 of about 25cm length can be straightened in one opera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com