Method for calibrating full-automatic visual inspection machines for products

A calibration method and visual inspection machine technology, which is applied in the calibration field of material sorting machines, can solve problems such as poor coordination of moving distance, inability to effectively pick up products, and machine failure to work normally, so as to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

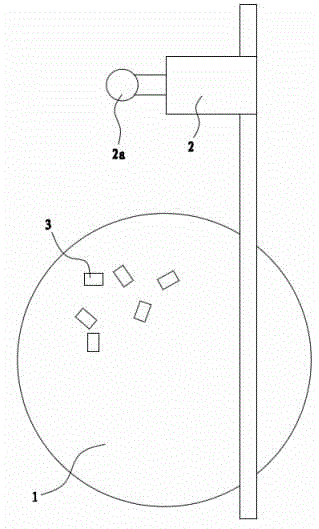

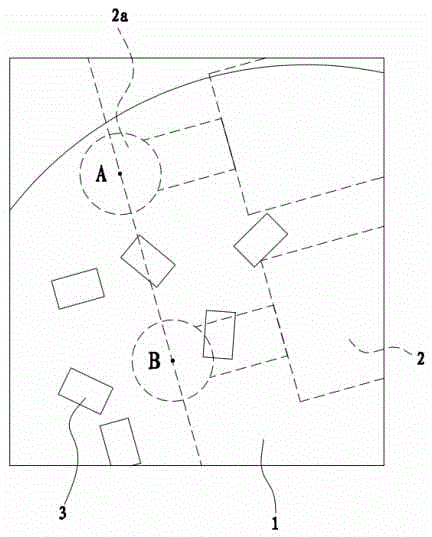

[0036] Such as figure 1 As shown, the product automatic visual inspection machine includes a turntable 1 and a linear motor 2 . During work, product 3 is placed on the turntable 1. In this visual inspection machine, there may be some inclinations in the setting angle of the imaging system, as in figure 2 As shown in , the path of the linear motor 2 in the field of view of the camera has a certain angle of inclination.

[0037] During the use of the visual inspection machine, there are uncertain factors, such as the offset of the imaging system, the offset of the turntable 1 and the linear motor 2, the reset of computer data, and the mechanical wear in the visual inspection machine, etc. 2. The product 3 cannot be picked up or the effect of picking up the product 3 is not good, so the visual inspection machine needs to be calibrated.

[0038] This calibration method includes the calibration of the path of the linear motor and the calibration of the center of the turntable. ...

Embodiment 2

[0061] This calibration method includes the calibration of the path of the linear motor and the calibration of the center of the turntable.

[0062] The linear motor 2 path calibration includes the following steps:

[0063] A1. Manipulate the linear motor 2 to move from the origin to the motor point 1 according to the preset displacement b1, and the motor point 1 is located in the field of view of the camera; the motor point 1 is as figure 2 Point A shown in ; the position of motor point 1 is located at 1 / 3 of the travel path of linear motor 2 in the camera field of view;

[0064] B1. Place a product 3 directly under the suction head 2a of the linear motor 2;

[0065] C1. Determine the coordinate p1 of the center point of the product 3 in step B1 in the field of view of the camera; specifically, use an image processing algorithm to obtain the center position of the product 3 . An imaging mechanism is set in the visual inspection machine to facilitate the imaging of the prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com