wind power transmission

A technology of transmission mechanism and wind power equipment, which is applied in the direction of wind power engines, engines, mechanical equipment, etc., to achieve the effect of simplifying the lubricant supply system and improving the volume flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]At the outset, it should be pointed out that identical parts are provided with the same reference numerals or the same component designations in the different described embodiments, wherein the disclosure contained in the entire description can be transferred as appropriate to the same reference numerals or the same component designations on the same part of the name. Likewise, positional indications selected in the description, such as top, bottom, side, etc., refer to the directly described and illustrated drawing and, in the event of a change in position, are meaningfully transferred to the new position.

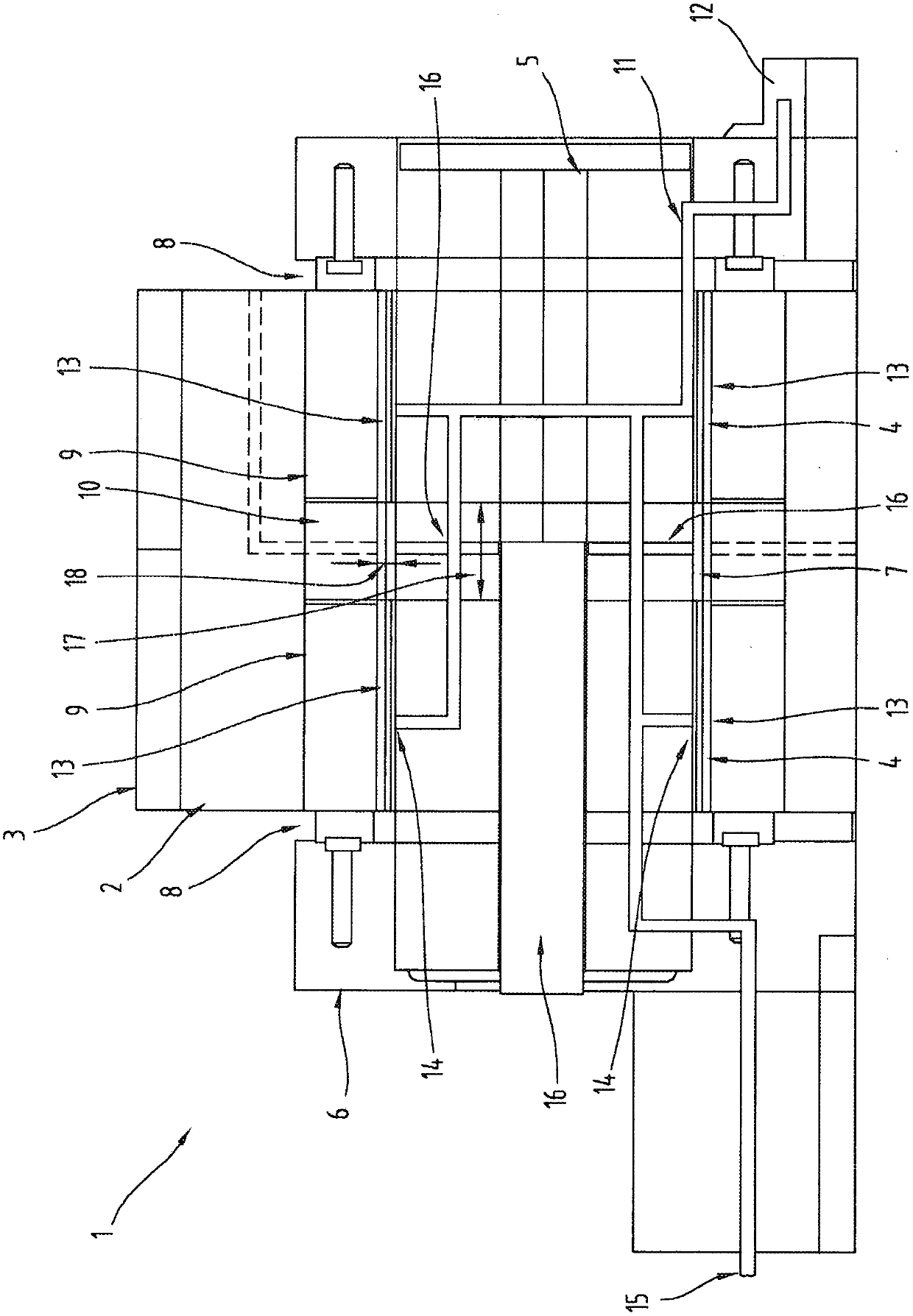

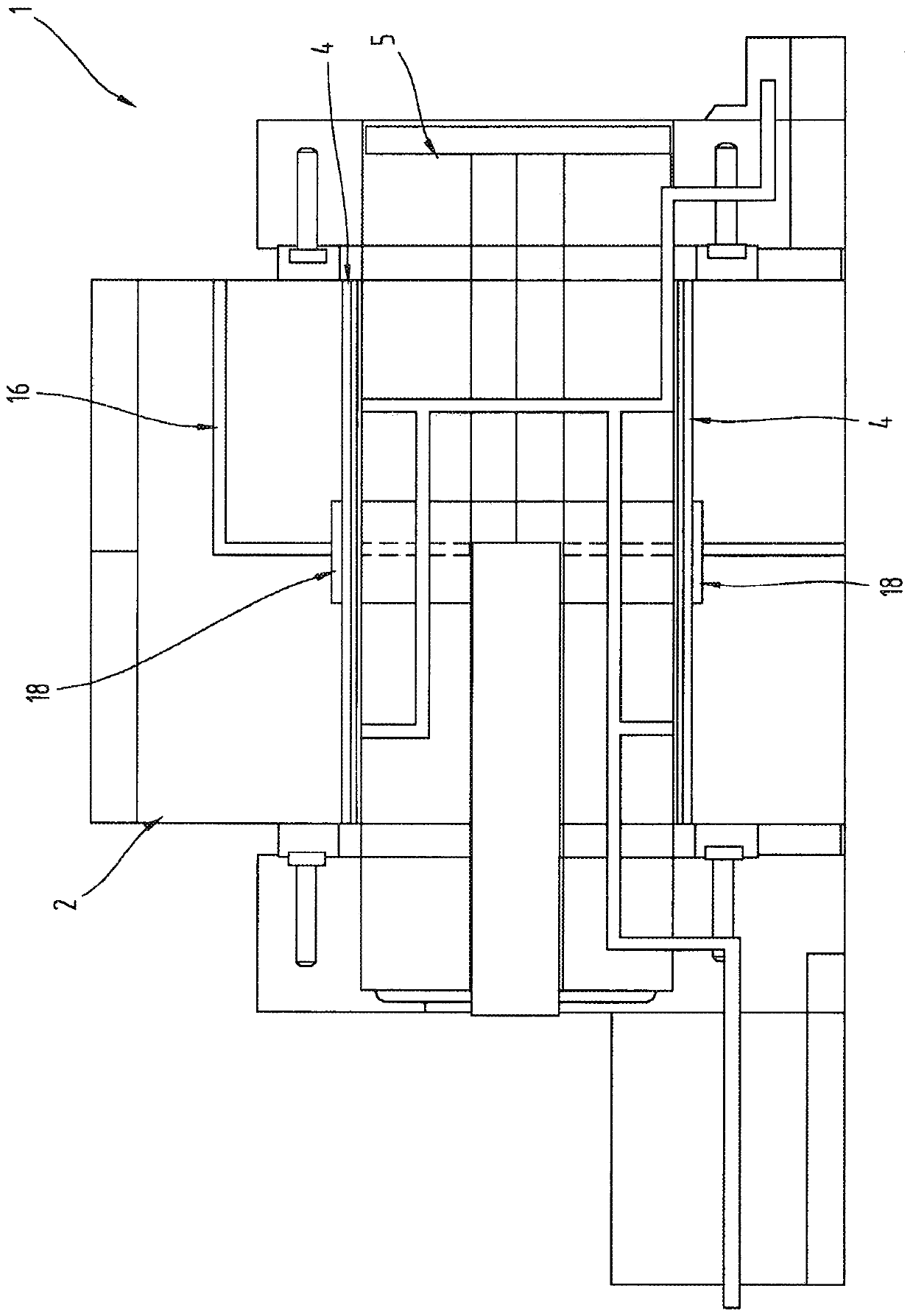

[0030] figure 1 A partial cross-section of the wind turbine gear 1 is shown. The wind turbine gear 1 is in particular designed in the form of a (single-stage) planetary gear.

[0031] As is known, a wind power installation has a tower, at the upper end of which a nacelle is arranged, in which nacelle the rotor is mounted with the rotor blades. The rotor is operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com