Seal leak detection device

A technology of sealing device and leak detection, which is applied in the direction of measuring device, fluid tightness test, machine/structural component test, etc., to achieve the effect of ingenious structural design, easy implementation and reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

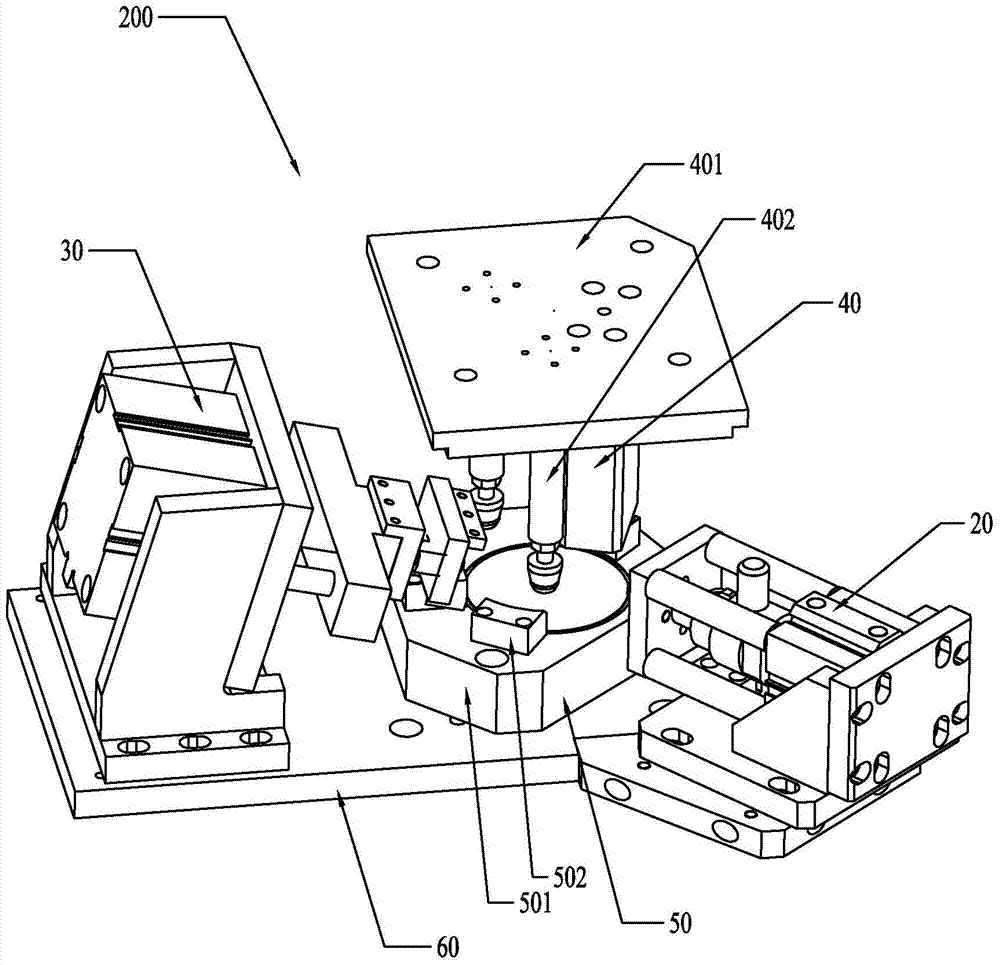

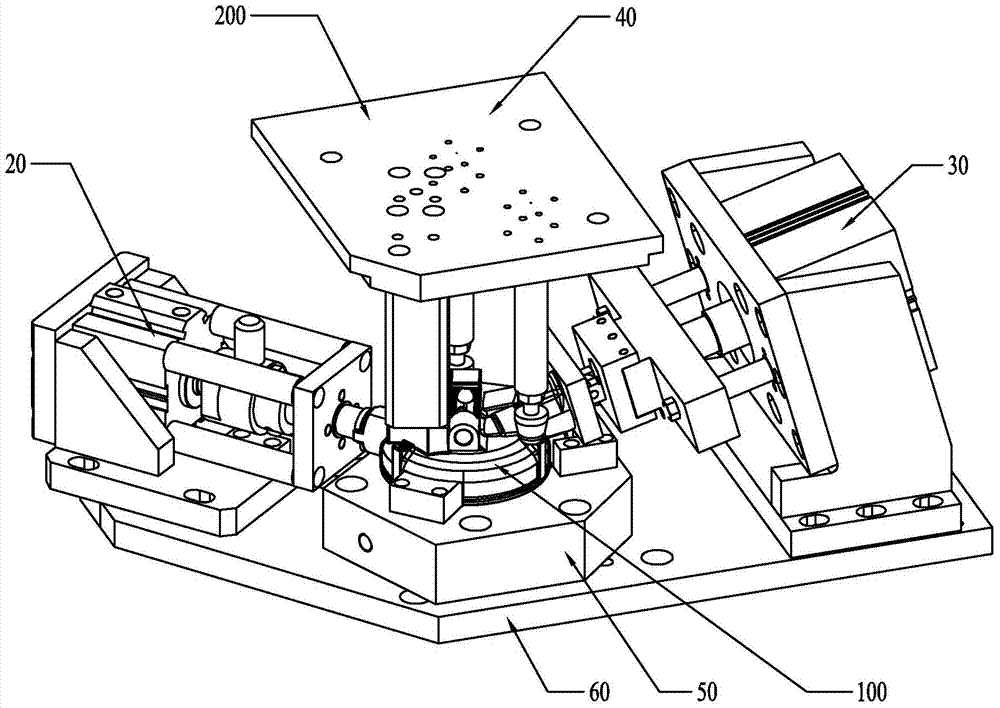

[0022] refer to Figure 2 to Figure 9 As shown, the leak detection device 200 of the present invention includes: a first sealing device 20 , a second sealing device 30 , an upper positioning device 40 , a lower positioning device 50 and an assembly bottom plate 60 .

[0023] Wherein, the assembly bottom plate 60 is used to make the first sealing device 20 , the second sealing device 30 , and the lower positioning device 50 form a whole, and they are all fixed on the assembly bottom plate 60 .

[0024] The upper positioning device 40 includes: a lower pressing actuator (not shown in the figure), an upper pressing plate 401 and more than one positioning column 402, the lower pressing actuator is arranged above the upper pressing plate 401 to drive it to move up and down, and the positioning column 402 is fixed on The bottom surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com