Constant-volume combustion technology adopting rotating valve to control opening and closing of combustion chamber and power system applying constant-volume combustion technology

A constant volume combustion and combustion chamber technology, applied in the combustion chamber, continuous combustion chamber, combustion method and other directions, can solve the problems of small intake area valve area, unfavorable flow rate, low utilization rate of windward area, etc., to improve the thrust-to-weight ratio, The effect of simple implementation and reduced processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose of the present invention, the technical solution and a bit clearer, the technical solution of the present invention will be clearly and completely described below. All other implementations obtained below fall within the protection scope of the present invention.

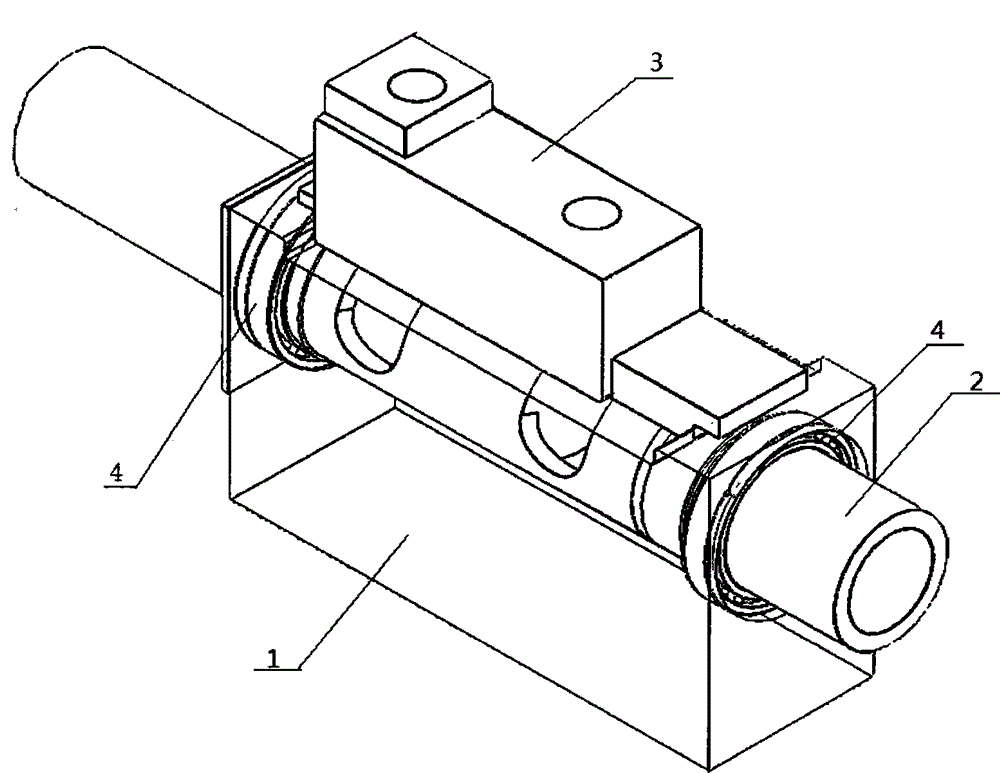

[0032] Such as figure 1 As shown, the device for implementing the constant volume combustion technology proposed by the present invention mainly includes a base 1 , a rotating shaft 2 , and a combustion chamber 3 .

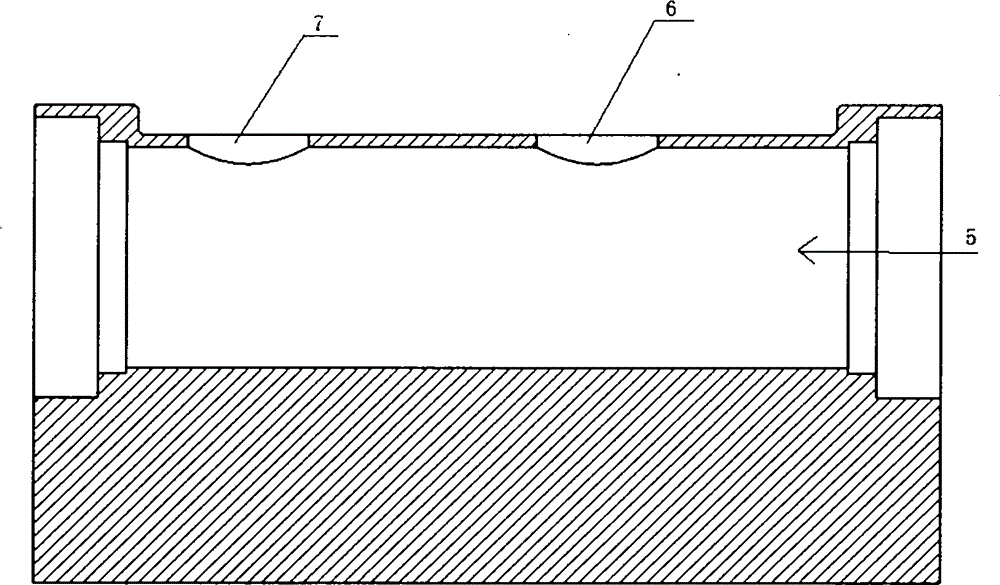

[0033] Such as figure 2 As shown, the middle of the base 1 is provided with a stepped through hole 5 , and the top of the base 1 is axially from the front to the back air intake hole 6 and exhaust hole 7 .

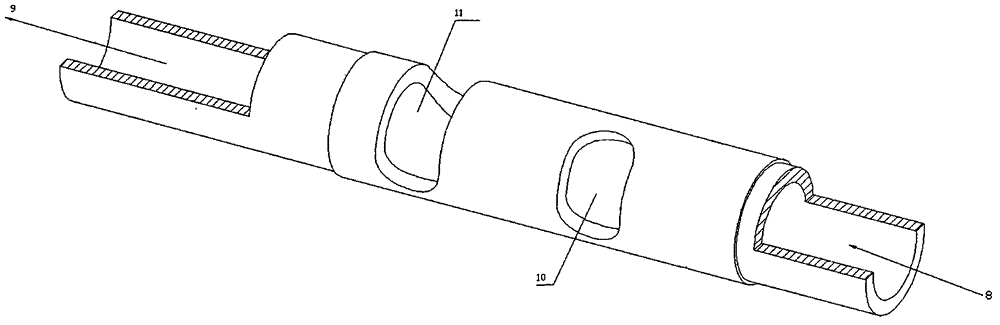

[0034] Such as image 3 As shown, the front end and the rear end of the rotating shaft 2 are respectively provided with an air intake passage 8 and an exhaust passage 9, and the two are not connected. The rotating shaft 2 is axially provided with an inlet pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com