Large-deformation flexible mechanism

A flexible mechanism and large deformation technology, applied in the field of hinges, can solve the problems of small motion stroke, small motion stroke of flexible hinges, and limitations in application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

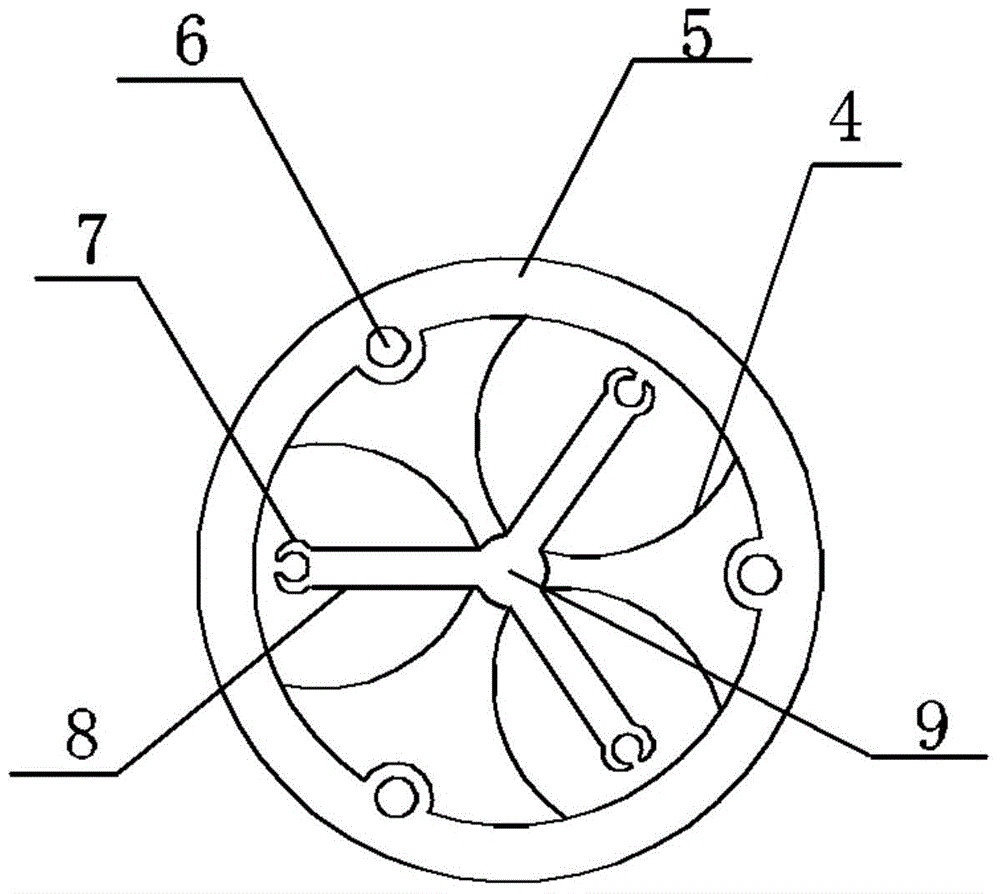

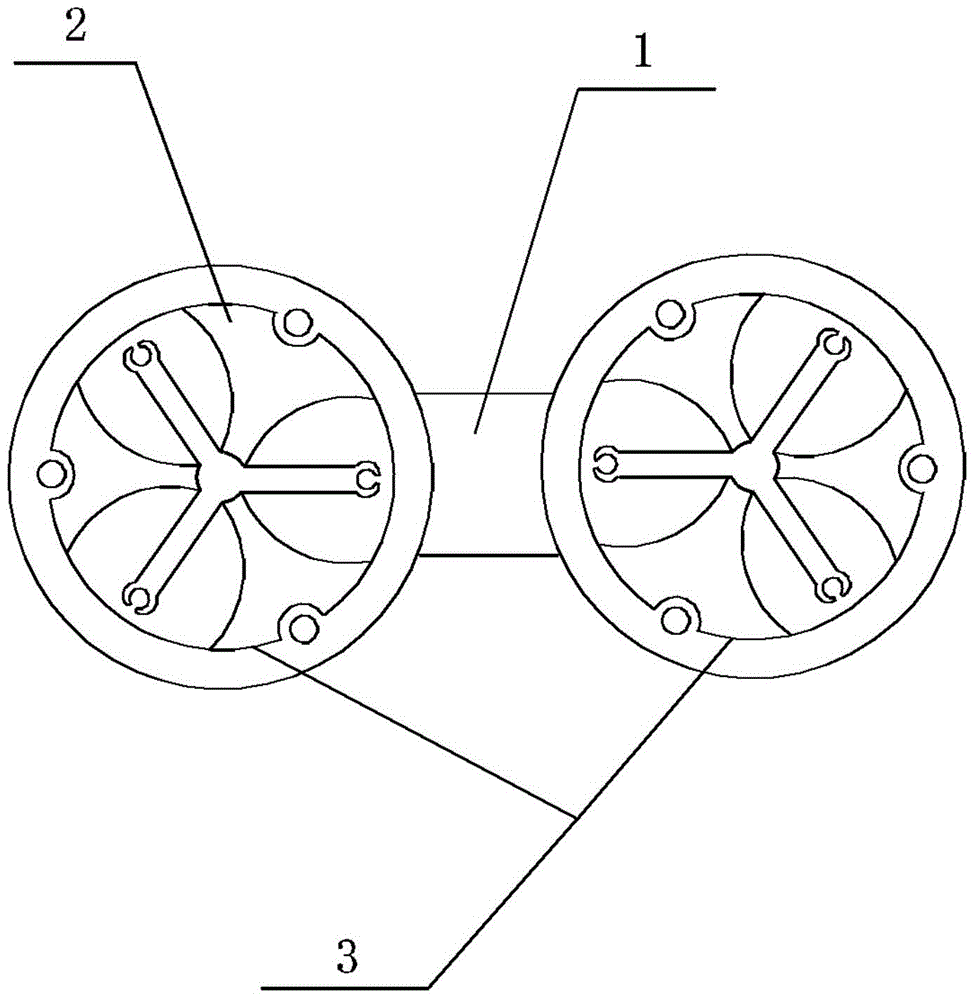

[0012] A large-deformation flexible mechanism is composed of two large-deformation flexible hinges 2 connected in series. The large-deformation flexible hinge 2 includes 6 curved sheet flexible units 4, 3 inner arms 8 and an outer ring 5. The 6 curved sheet flexible One end of the unit 4 is converged and fixed on the center point 9, and the other end is evenly distributed and fixed on the outer ring 5. The six curved thin plate flexible units 4 are symmetrical to each other to form a curved thin plate flexible unit group. Three groups of curved thin plate flexible unit groups are about the central point 9. The center is symmetrical, and the three inner arms 8 are located at the symmetrical axes of the three sets of curved thin plate flexible unit groups. One end of the inner arm 8 is fixed on the center point 9, and the other end is connected to the mechanical input interface 7. The outer ring A mechanical output interface 6 is provided between two groups of adjacent curved thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com