Booster pump and boosting method thereof

A booster pump and pressure technology, which is applied in the field of hydraulic pressure boosting, can solve problems such as application limitations, failure to meet operating needs, and plunger breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

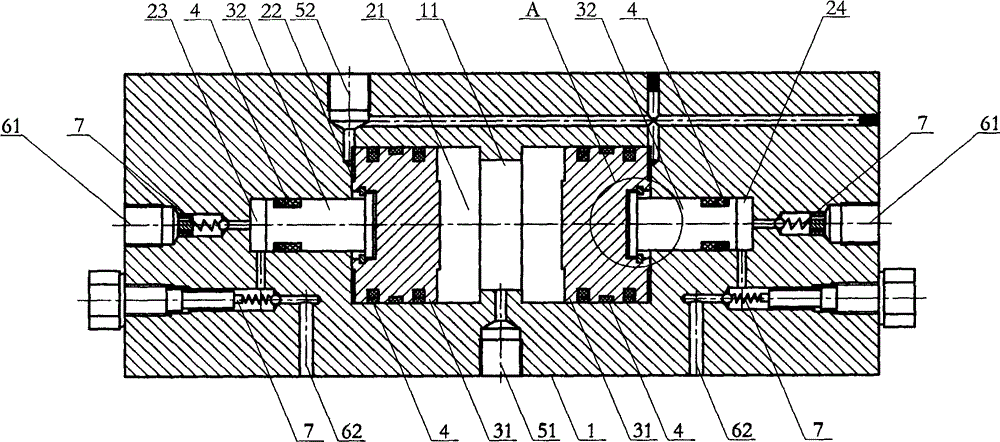

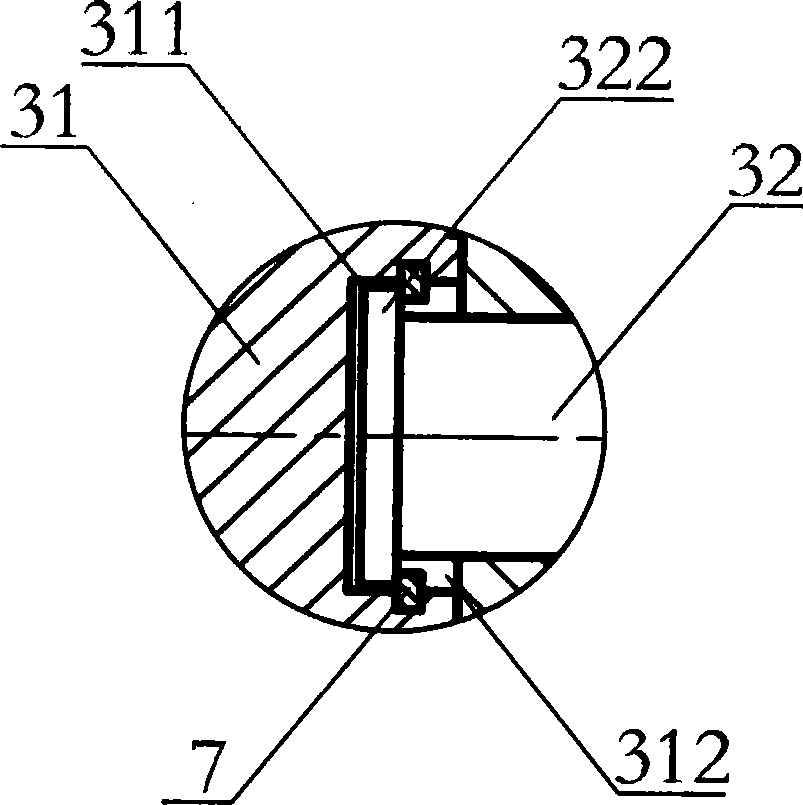

[0031] Such as figure 1 , 3 , shown in 4 and 5: a booster pump and its boosting method, comprising a booster pump main body 1, the inner middle part of the booster pump main body 1 is provided with a middle chamber, a left chamber 23 and a right chamber 24 , the middle part of the inner wall of the middle chamber is provided with a positioning column 11, and the two sides of the positioning column 11 are provided with piston rods. The positioning column 11 can position the two piston rods to prevent the end faces of the two piston rods from being separated by oil. , the piston rod is composed of an upper piston rod 31 and a lower piston rod 32, the cross-sectional area S1 of the upper piston rod 31 is at least twice the cross-sectional area S2 of the lower piston rod 32, and the upper piston rod 31 is arranged in the middle chamber, The lower piston rod 32 is disposed in the left chamber 23 and the right chamber 24 .

[0032] The middle chamber is divided into a drive chambe...

Embodiment 2

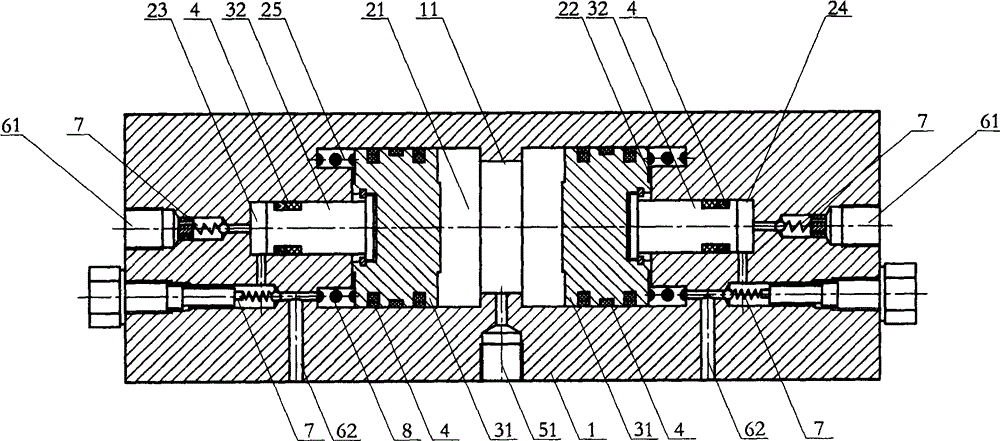

[0043] Such as figure 2 , 3, shown in 4 and 6: a booster pump and its boosting method, comprising a booster pump main body 1, the inner middle part of the booster pump main body 1 is provided with a middle chamber, a left chamber 23 and a right chamber 24 , the middle part of the inner wall of the middle chamber is provided with a positioning column 11, and the two sides of the positioning column 11 are provided with piston rods. The positioning column 11 can position the two piston rods to prevent the end faces of the two piston rods from being separated by oil. , the piston rod is composed of an upper piston rod 31 and a lower piston rod 32, the cross-sectional area S1 of the upper piston rod 31 is at least twice the cross-sectional area S2 of the lower piston rod 32, and the upper piston rod 31 is arranged in the middle chamber, The lower piston rod 32 is disposed in the left chamber 23 or the right chamber 24 .

[0044] The middle chamber is divided into a drive chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com