Process for preparing Ti-Al-N series high-temperature wear-resistant films with different ingredients by virtue of single sputtering

A high-temperature wear-resistant and sub-sputtering technology, applied in the field of high-temperature wear-resistant thin films, can solve the problems of difficult preparation of alloy targets, high hardness, and high cost, and achieves high cost, simplified research process, and complicated target making. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

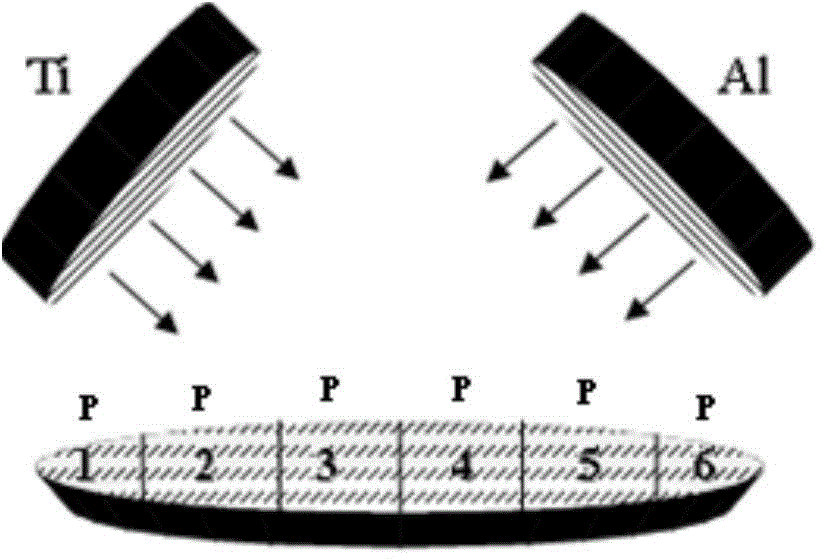

[0020] The method of double-target reactive co-sputtering is adopted. The double targets are made of pure metal Ti target and Al target. The two targets are placed symmetrically at 90° relative to each other. The angles are all 45°, such as figure 1 Show. Both targets have a purity of 99.99% and are of the same size.

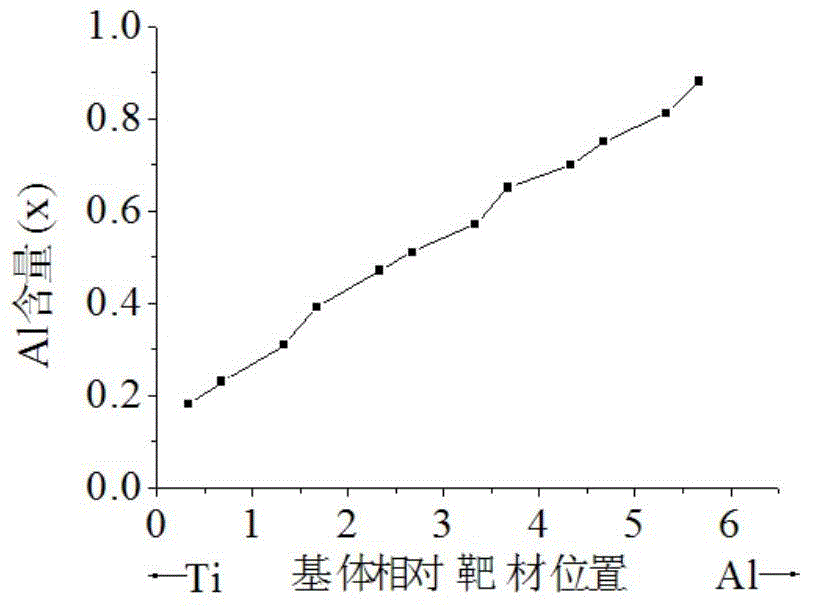

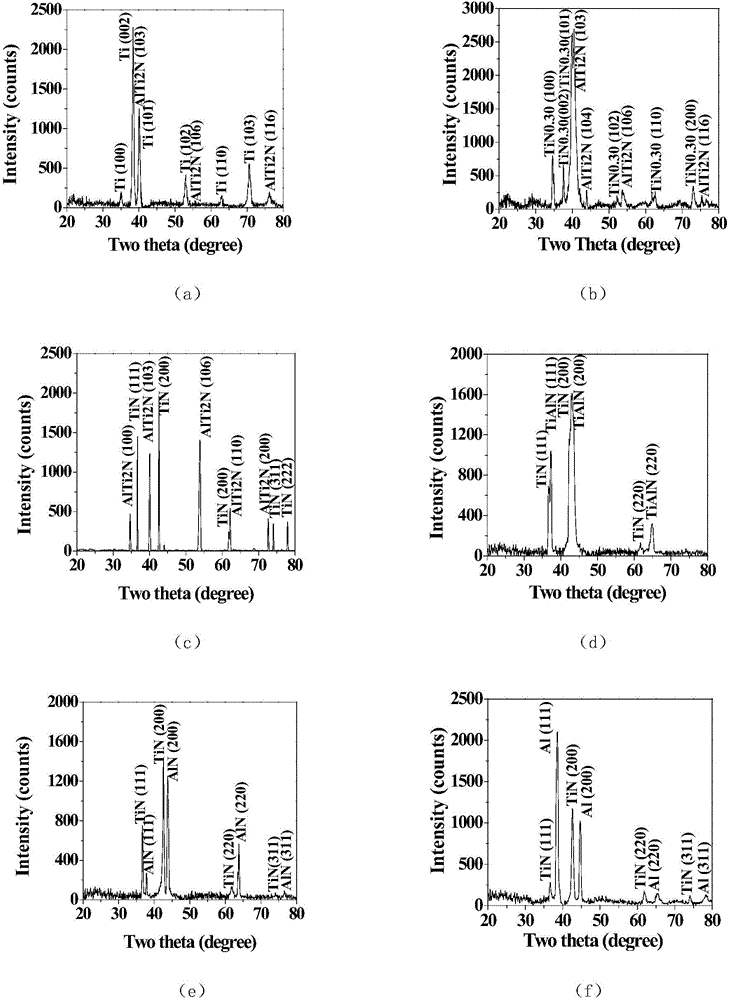

[0021] In order to systematically study the differences in film structure, morphology, and performance at different sputtering positions, the sample stage is divided into six areas on average, and the positions closest to the Ti target and Al target are marked as P1 and P6, respectively. Numbered sequentially, 12 substrates were placed on average in these 6 areas along the centerline of the double target and labeled from S1 to S12, among which the substrate closest to the titanium target was marked as S1, and the substrate closest to the aluminum target was marked as S12.

[0022] Before the coating starts, the background vacuum is pumped to higher than 5×10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com