Coal gas utilization method realized by coal-tar fraction hydro-upgrading and LNG manufacturing combination

A technology for hydrogenation and upgrading, coal tar, applied in chemical instruments and methods, hydrogen, petroleum industry, etc., can solve the problems that hydrogen cannot achieve rationalization and maximization of resource utilization, and there is no integrated solution for rich gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1, the combined operation of coal tar fraction hydrotreating and LNG production.

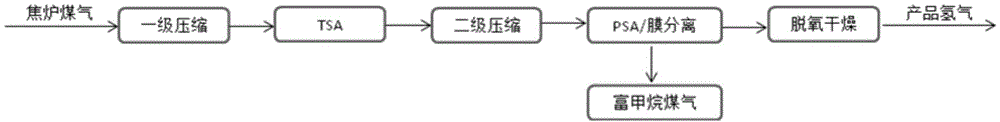

[0031] Such as figure 2 As shown, the following steps are included in sequence: primary compression process, TSA process, secondary compression process, pre-hydrogenation / sulfur tolerance conversion process, deacidification process, hydrodesulfurization process, methanation process, PSA-H2 process and LNG In the product process, the product hydrogen is obtained through the PSA-H2 process and the deoxygenation drying process, and the LNG product is obtained through the LNG product process.

[0032] The deacidification process includes MDEA decarburization process and desulfurization process, and adjusts deCO2 according to the change of raw material composition and flow rate 2 In order to achieve carbon and hydrogen balance, the LNG product process includes compression process, purification process and liquefaction process in sequence. The hydrogen separated in the liquefaction...

Embodiment 2

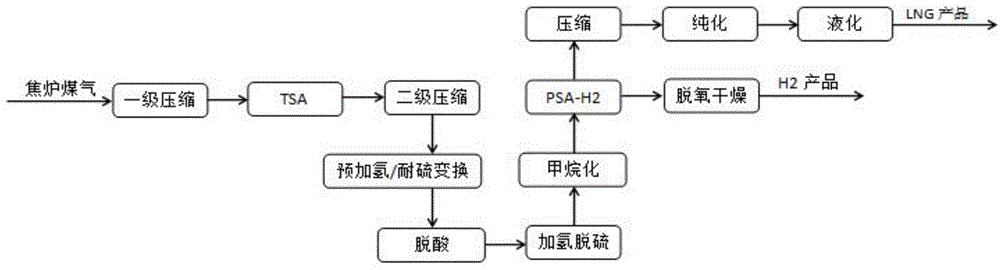

[0034] Embodiment 2, the coal tar distillate hydrotreating upgrading process operates independently.

[0035] Such as image 3 As shown, it includes the following steps in sequence: primary compression process, TSA process, secondary compression process, PSA-H2 process and deoxidation drying process. Coke oven gas can obtain product hydrogen after the above steps.

Embodiment 3

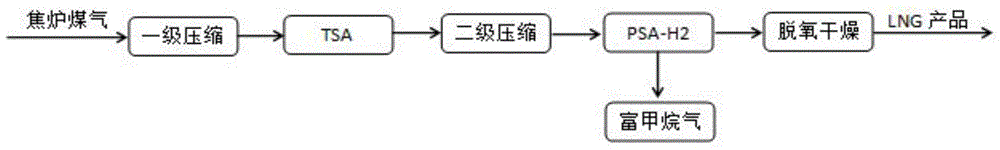

[0036] Embodiment 3, the process of producing LNG operates independently.

[0037] Such as Figure 4 As shown, it includes the following steps in sequence: primary compression process, TSA process, secondary compression process, pre-hydrogenation process, hydrodesulfurization process, methanation process, PSA-H2 process, compression process, purification process and liquefaction process, coke After the furnace gas goes through the above steps, the excess hydrogen is sent out from the PSA-H2 process, and the LNG product is obtained after the liquefaction process.

[0038] In Embodiments 1, 2, and 3, additional hydrogen can be obtained through the pre-hydrogenation / sulphur-resistant conversion process (the range of conversion is 0-96%) according to the raw material composition and flow conversion, so that the device can be operated in combination or Each independent operation can achieve carbon and hydrogen balance, meet the needs of the process, and also ensure the safe operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com