Material-distributing device for refuse pyrolysis gasification furnace

A technology of pyrolysis gasification and material distribution device, which is applied in the direction of coke oven, indirect heating dry distillation, special form dry distillation, etc. It can solve the problems of uneven feeding, incomplete pyrolysis gasification of waste, and raw material area, so as to improve efficiency , simple structure and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

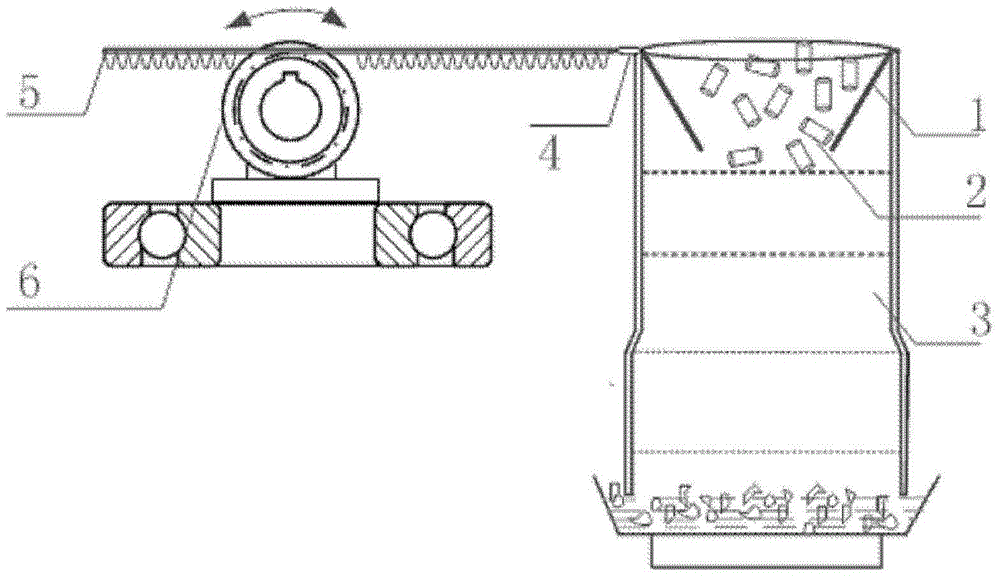

[0020] see figure 1 and figure 2 .

[0021] The waste pyrolysis gasification furnace material distribution device of the present invention is composed of two parts: a driving transmission and a distribution mesh screen, and the whole device is arranged between the hydraulic feeder and the feed port of the pyrolysis gasification furnace.

[0022] The transmission screw rod 5 of the present invention is placed on the cylinder transmission gear 6, and the transmission screw rod 5 is connected to the cloth mesh screen 1 through the transmission pulley 4. Cylindrical drive gear 6 is powered by the drive transmission motor of the hydraulic feeder.

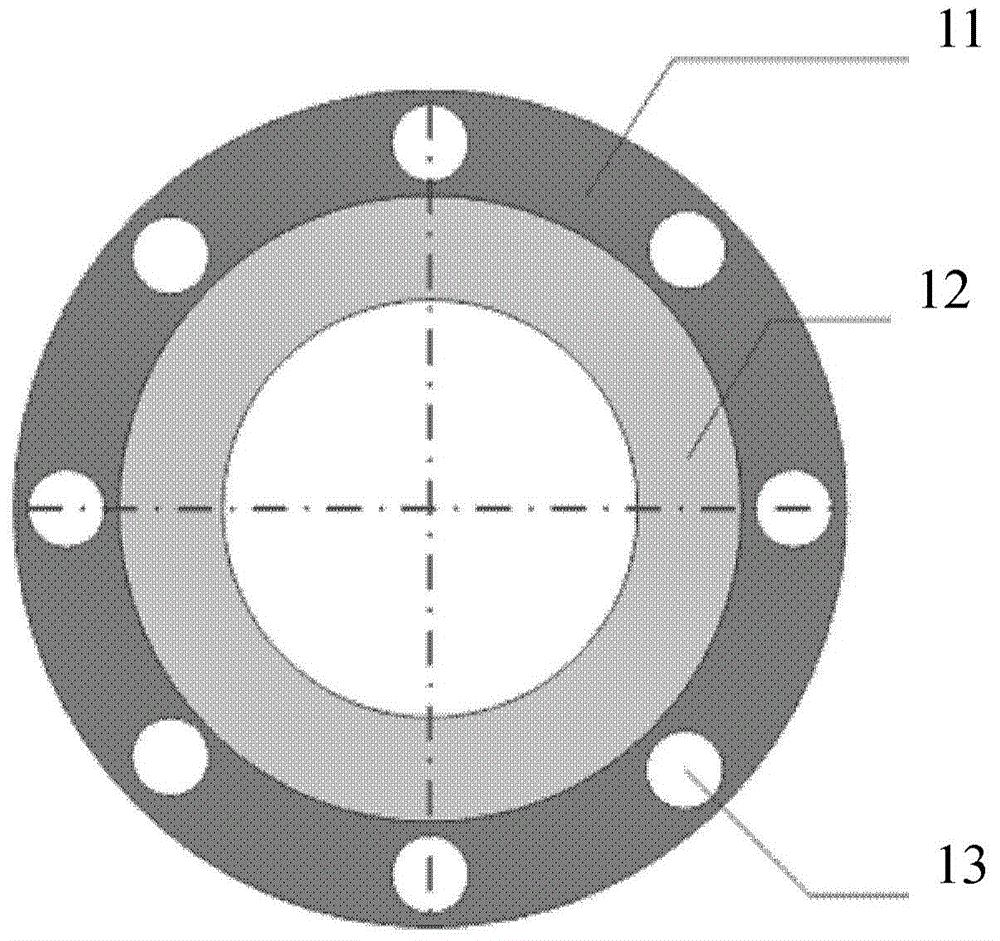

[0023] The distribution screen 1 is made of round table-shaped stainless steel, and the feed port 11 of the distribution screen 1 is installed on the feed port of the pyrolysis gasification furnace, and the feed port 11 of the distribution screen 1 is connected with the feed port of the pyrolysis gasification furnace. The diameters a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com