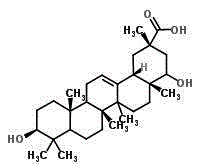

Purification method of maytenfolic acid

A purification method, the technology of folic acid, applied in the field of natural medicinal chemistry, can solve the problems of low product purity, complicated operation, difficult industrial production, etc., and achieve the effect of high product purity and simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Take the dried euonymus and grind it, pass through a 20-mesh sieve, and collect the coarse powder for later use; dissolve the cellulase in distilled water according to the ratio of 0.1g cellulase / L water, stir evenly, add hydrochloric acid solution dropwise, and adjust the pH value 4. Add euonymus coarse powder into the above-mentioned cellulase aqueous solution at a mass volume ratio of 1:1, stir evenly, heat in a water bath to 45°C, perform constant temperature enzymatic hydrolysis for 1 hour, then raise the temperature to 60°C, heat for 20 minutes, and inactivate the enzyme , to obtain the enzymatic hydrolysis mixture; add a solid-liquid ratio of 1:3, 30% ethanol aqueous solution to the above enzymolysis mixture, conduct ultrasonic extraction at a frequency of 20KHz, and a temperature of 50°C, filter, and ultrasonically extract the filter residue once, and combine the filtrates Concentrate under reduced pressure until there is no alcohol smell, collect the concentrate...

Embodiment 2

[0023] Take the dried euonymus raw material and grind it through a 40-mesh sieve to collect the coarse powder for later use; dissolve the cellulase in distilled water according to the ratio of 0.3g cellulase / L water, stir evenly, add hydrochloric acid solution dropwise, and adjust the pH value to 4. Add euonymus coarse powder into the aqueous solution of cellulase at a mass volume ratio of 1:3, stir evenly, heat in a water bath to 45°C, perform constant temperature enzymolysis for 1.5h, then raise the temperature to 70°C, heat for 30min, and inactivate the enzyme , to obtain the enzymolysis mixture; add a solid-liquid ratio of 1:4, 30% ethanol aqueous solution to the above enzymolysis mixture, perform ultrasonic extraction at a frequency of 40KHz and a temperature of 60°C, filter, and ultrasonically extract the filter residue twice, and combine The filtrate was concentrated under reduced pressure until there was no alcohol smell, and the concentrated solution was collected for ...

Embodiment 3

[0025] Take the dried euonymus raw material and pulverize it, pass through a 60-mesh sieve, and collect the coarse powder for later use; dissolve the cellulase in distilled water according to the ratio of 0.5g cellulase / L water, stir evenly, add hydrochloric acid solution dropwise, and adjust the pH value 5. Add euonymus coarse powder into the aqueous solution of cellulase at a mass volume ratio of 1:5, stir evenly, heat in a water bath to 50°C, perform constant temperature enzymolysis for 2 hours, then raise the temperature to 80°C, heat for 40 minutes, and inactivate the enzyme. The enzymolysis mixture is obtained; add a solid-liquid ratio of 1:5, 30% ethanol aqueous solution to the enzymolysis mixture, perform ultrasonic extraction at a frequency of 40KHz and a temperature of 70°C, filter, and ultrasonically extract the filter residue for 3 times, and combine the filtrates to reduce Concentrate under pressure until there is no alcohol smell, collect the concentrated solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com