Scissors fork lifting type auxiliary supporting mechanism capable of being locked at random position

An auxiliary support and arbitrary position technology, which is applied in the direction of lifting frames and lifting devices, can solve the problems of limited specifications of the adjustment pad 2', small size of the adjustment pad 2', and excessive changes in the vertical size of the mechanism, so as to facilitate manual operation , the effect of reducing the requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

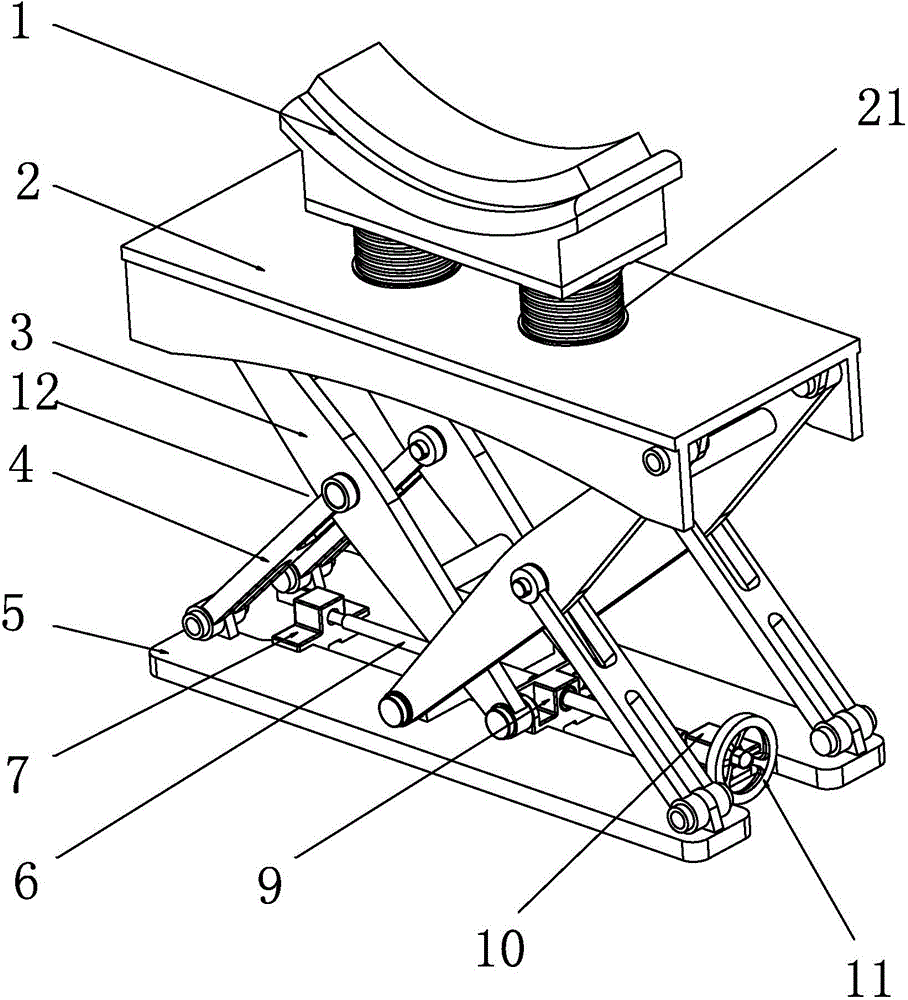

[0024] Such as figure 2 As shown, a scissor lifting auxiliary support mechanism that can be locked at any position in the present invention includes a bracket 1 and a top plate 2 below it. The bracket 1 and the top plate 2 are supported by two vertical Disc springs 21 arranged parallel to each other are fixedly connected. A bottom plate 5 is arranged below the top plate 2, and a screw rod 6 is arranged horizontally along the length direction of the bottom plate 5. For the convenience of fixing the screw rod 6 and ensuring the fixing effect of the screw rod 6, the screw rod 6 passes through the fixing seats 7, 7, The second fixed seat 10 is installed on the base plate 5 . Both ends of the screw rod 6 are fixed by two fixed seats, and its own movement is restricted. During the lifting movement of the supporting mechanism, the screw rod 6 will not move along its own axial or radial direction, effectively ensuring the adjustment accuracy of the lifting movement.

[0025] combin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com