Fully enclosed robot laser automatic welding machine for assembling automobile lamps

A technology for automatic welding machines and car lights, applied in laser welding equipment, welding equipment, welding equipment, etc., can solve the problems of backward research and difficulty in ensuring the quality stability and consistency of welded parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below according to the drawings and embodiments.

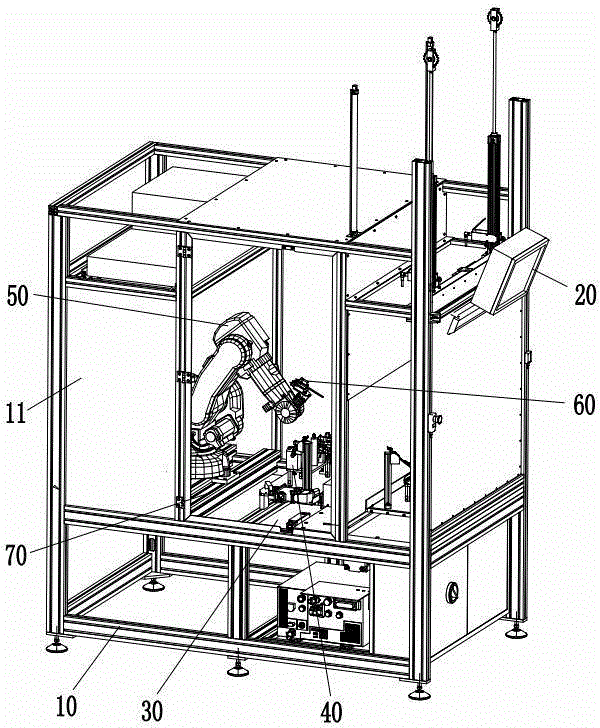

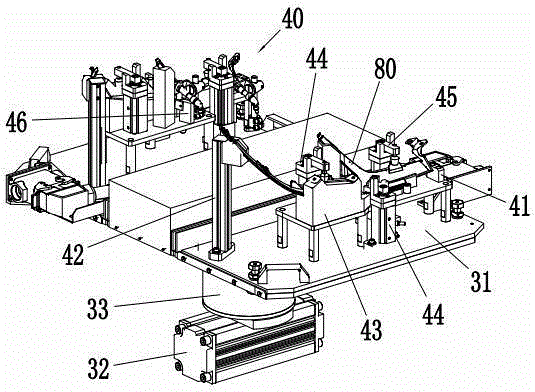

[0016] Such as figure 1 and figure 2 As shown, a fully enclosed robotic laser automatic welding machine for automobile lamp assembly described in the embodiment of the present invention includes a closed main body 10 and a PLC safety control device 20 arranged on the main body. The main body 10 has a closed door 11, The main body 11 is provided with a rotary table device 30, the rotary table device 30 includes a rotatable table 31, the table 31 is provided with a welding fixture 40, and a six-axis robot 50 is installed on the side of the table 31 in the main body 10 , the welding working end of the six-axis robot 50 is equipped with a laser generator 60 , and the PLC safety control device 20 is connected to the rotary table device 30 , the six-axis robot 50 and the laser generator 60 .

[0017] The rotary table device 30 includes a rotary motor 32 arranged bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com