Wired segment electrowelding support

A linear and arc-shaped bracket technology, applied in welding equipment, gas flame welding equipment, metal processing equipment and other directions, can solve the problems of poor processing accuracy, uneven placement in sections, etc., and achieve the effect of preventing melting and deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

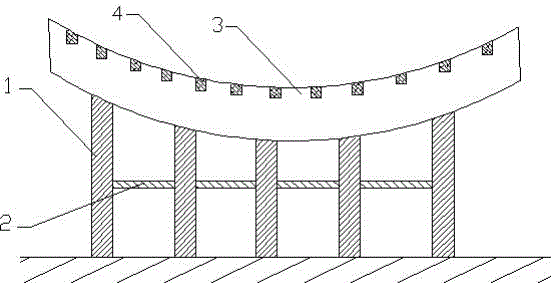

[0009] see figure 1 , the present invention relates to a wire-type segmented electric welding support, which includes a plurality of five uprights 1 arranged in a straight line, a crossbeam 2 is connected to the middle of two adjacent uprights 1, and the top of the uprights 1 is provided with An arc-shaped support 3, the concave surface of the arc-shaped support 3 faces upward, and eight to sixteen support plates 4 arranged at intervals are arranged on the top of the side of the arc-shaped support 3 along the length direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com