Preparation method for carboxymethyl chitosan gel ball

A carboxymethyl chitosan gel ball, carboxymethyl chitosan technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problem of low swelling degree, pollutants Low removal rate and other problems, to achieve the effect of high toughness, convenient solid-liquid separation, and suitable for large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

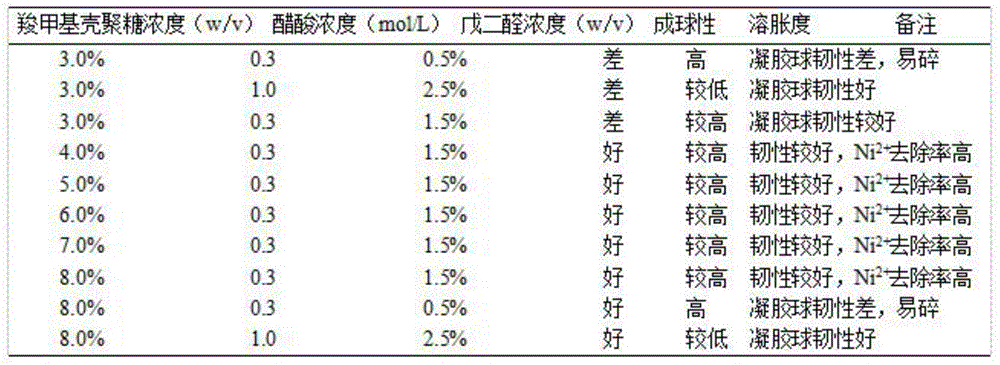

example 1

[0048] Example 1: Weigh 1.5g carboxymethyl chitosan in a 100mL plastic beaker, add 50mL deoxygenated water and magnetically stir to dissolve, and the solution concentration is 3.0% (w / v). Use a pipette gun to pipette 3mL carboxymethyl chitosan solution dropwise into a glass beaker filled with 50mL0.3mol / L acetic acid solution to form a pellet, and strengthen it in the acid for 40min, so that the pellet becomes transparent and solid white small ball. Then put the strengthened pellets into an Erlenmeyer flask containing 50 mL of 0.5% glutaraldehyde solution (containing 5 mL of 0.3 mol / L acetic acid solution), and cross-link at 40° C. for 9 to 12 hours. Rinse off excess glutaraldehyde solution with ultra-pure water, then immerse the pellet in 1mol / L NaOH solution, wait until the pellet turns white into light yellow transparent pellet, then rinse off excess lye with ultra-pure water. The gel balls prepared under this condition have poor spheroidity, high degree of water swelling,...

example 2

[0049] Example 2: Weigh 1.5g of carboxymethyl chitosan in a 100mL plastic beaker, add 50mL of deoxygenated water and magnetically stir to dissolve, and the solution concentration is 3.0% (w / v). Use a pipette gun to pipette 3mL carboxymethyl chitosan solution dropwise into a glass beaker filled with 50mL1.0mol / L acetic acid solution to form a pellet, and strengthen it in the acid for 15min, so that the pellet becomes transparent and solid white small ball. Then put the strengthened pellets into an Erlenmeyer flask containing 50 mL of 2.5% glutaraldehyde solution (containing 5 mL of 0.3 mol / L acetic acid solution), and cross-link at 60° C. for 3 to 5 hours. Rinse off excess glutaraldehyde solution with ultra-pure water, then immerse the pellet in 1mol / L NaOH solution, wait until the pellet turns white into light yellow transparent pellet, then rinse off excess lye with ultra-pure water. The gel balls prepared under this condition have poor spheroidity and low water swelling deg...

example 3

[0050] Example 3: Weigh 1.5g carboxymethyl chitosan in a 100mL plastic beaker, add 50mL deoxygenated water and magnetically stir to dissolve, the solution concentration is 3.0% (w / v). Use a pipette gun to pipette 3mL carboxymethyl chitosan solution dropwise into a glass beaker filled with 50mL0.3mol / L acetic acid solution to form a pellet, and strengthen it in the acid for 40min, so that the pellet becomes transparent and solid white small ball. Then put the strengthened pellets into an Erlenmeyer flask containing 50 mL of 1.5% glutaraldehyde solution (containing 5 mL of 0.3 mol / L acetic acid solution), and cross-link at 60° C. for 5 to 7 hours. Rinse off excess glutaraldehyde solution with ultra-pure water, then immerse the pellet in 1mol / L NaOH solution, wait until the pellet turns white into light yellow transparent pellet, then rinse off excess lye with ultra-pure water. The gel balls prepared under this condition have poor spheroidity, high water swelling degree, good to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com