Multi-stage agglomeration and rotational flow combined method for removing liquid from gas

A technology of gas and swirling, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, etc., can solve problems such as weakening of swirling effects, and achieve the effects of easy processing, simple structure, and improved liquid removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

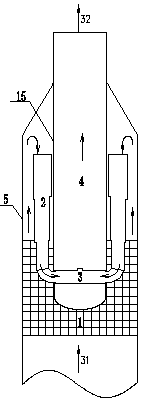

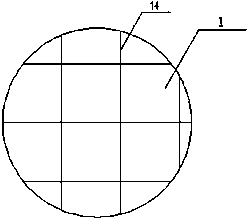

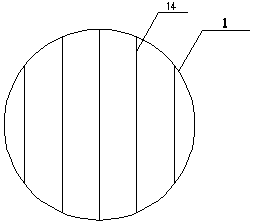

[0051] It is used for dehydration of flue gas in wet flue gas desulfurization unit. The flue gas volume is 200,000 standard cubic meters per hour, the water content in the flue gas is 97099kg / h, the diameter of the tower body is 6000mm, the coalescing area is in the form of a grid, 150mm below the multi-stage cyclone eliminator, the channel size is 30mm, and the height is 1000mm. It is a hydrophilic plastic, and six sets of multi-stage cyclone separators of the same size are set between the exhaust tube and the tower body. Each set of separators has three stages, the shell diameter D1=800mm, the height L1=1440mm, D2= 680mm , L2=1224mm, D3=560mm, L3=1008mm, d=2750mm, H=420mm, α=0°, S=60mm, there are 4 swirl blades in each stage, the total pressure drop of the dehydrator is 1085Pa, and the exhaust gas contains The amount of water is almost zero.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com