Combustion, heat-exchange and emitter device

An emitter and device technology, applied in the field of thermal photovoltaic devices, can solve the problems of high cost and complicated manufacturing of emitter devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

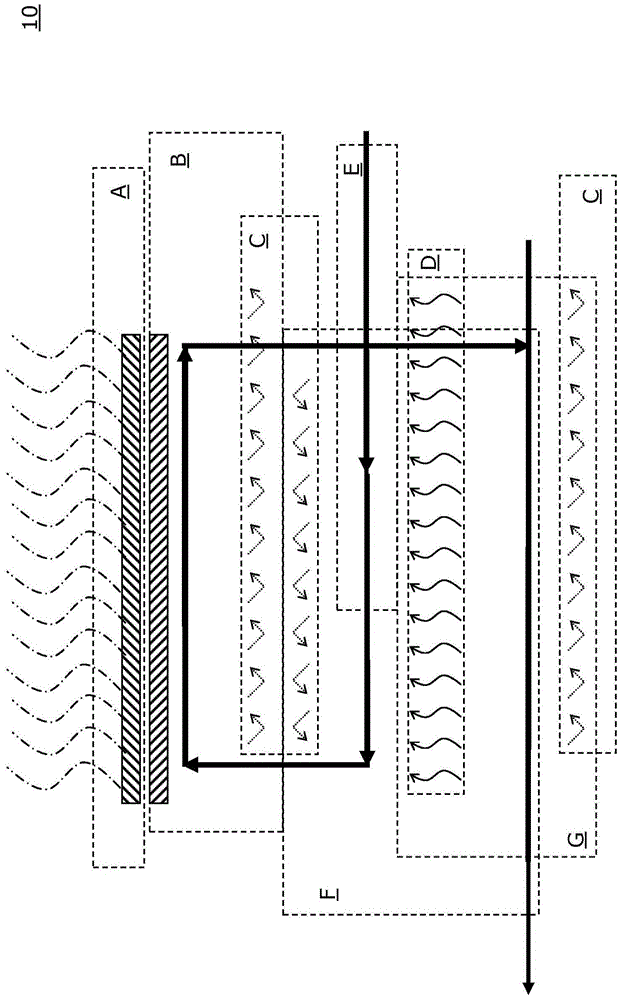

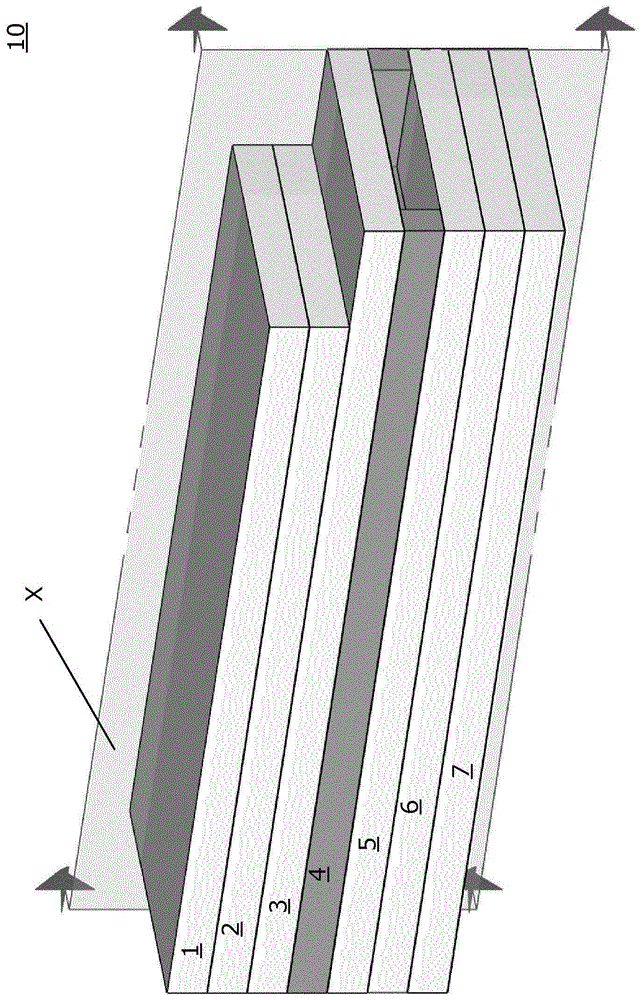

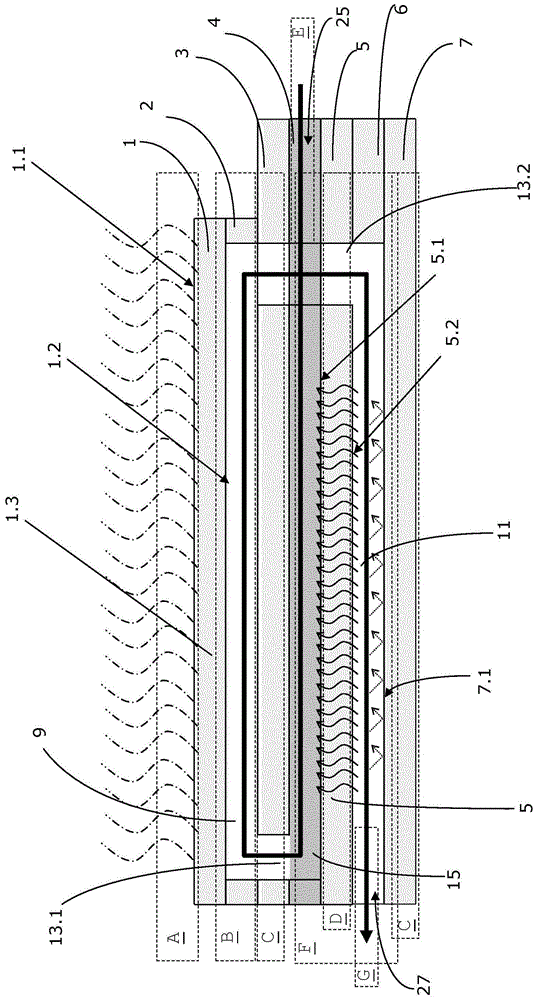

[0095] For production such as Figure 2A to Figure 3B Shown is a particularly preferred embodiment of the combustion, heat exchange and emitter device 10 of the present invention, the method further comprising the following steps:

[0096] - providing a combustion layer 2 between the emitter layer 1 and the heat conducting layer 5, the combustion layer 2 being configured and arranged to at least partially define said combustion chamber 9;

[0097] - between the emitter layer 1 and the heat conducting layer 5 is provided a further heat conduction preventing layer 3 which separates said preheating chamber 15 from the combustion chamber 9; this further heat conduction preventing layer 3 is arranged and configured to at least partially define said second flow channel 13.2, and at least partially define said first flow channel 13.1; and

[0098] - An output layer 6 is arranged between the heat conducting layer 5 and the heat conduction preventing layer 7 , the output layer 6 being...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com