Clamping and noise reducing structure for epoxy cast dry-type transformer core

A dry-type transformer and iron core clamping technology, applied in the field of transformer manufacturing, can solve the problems of difficulty in assembling the hoop structure, difficult to meet the requirements of rigidity, and small size of channel steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

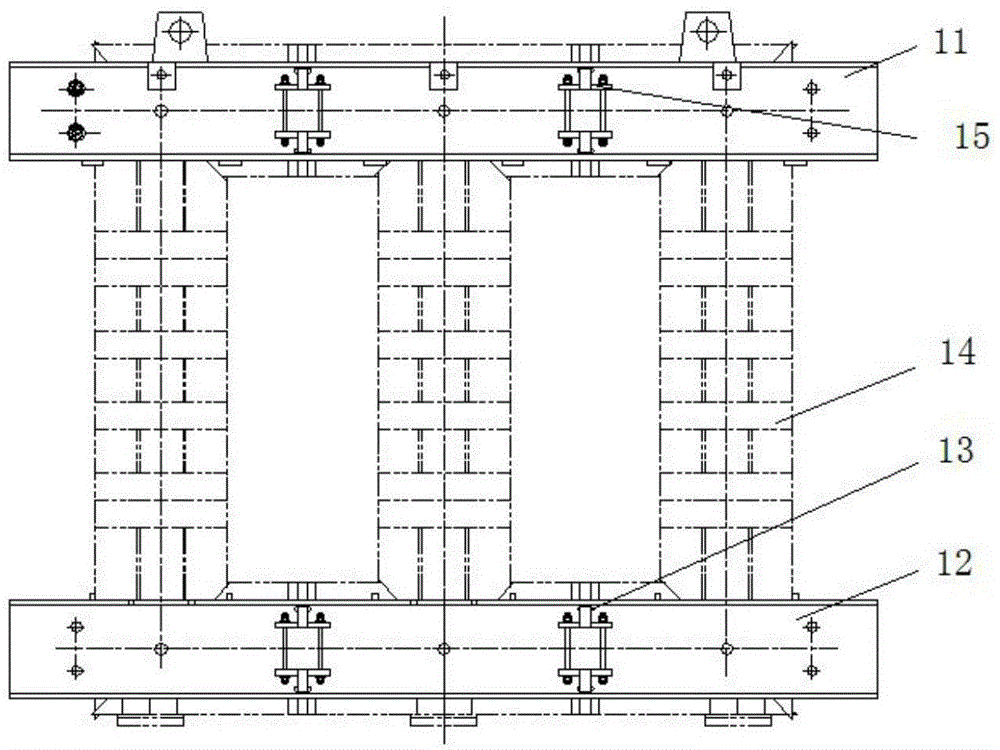

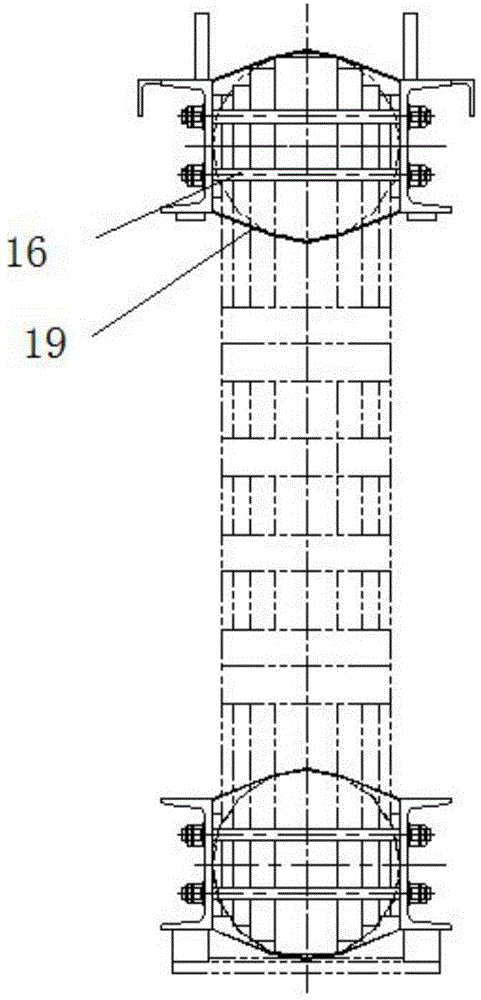

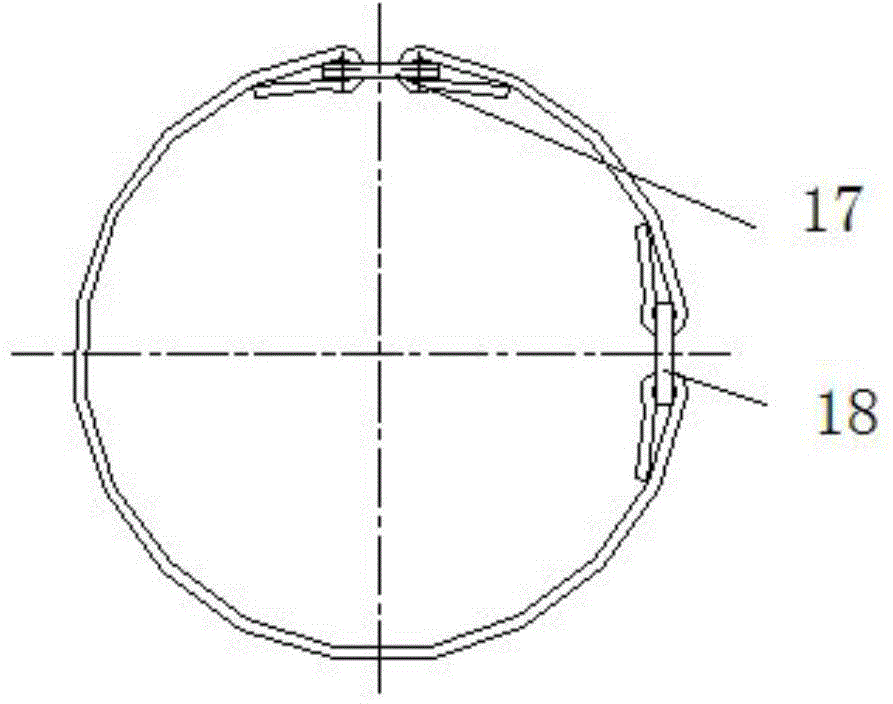

[0020] An epoxy cast dry-type transformer core clamping noise reduction structure, see Figure 5 to Figure 8 , the structure includes a drawstring 1, a drawstring support plate 2 and a tightening bolt 3, and the drawstring support plate 2 is welded on the upper and lower end faces of the upper clamp 6 and the lower clamp 7; the drawstring is made of a flat strip stainless steel plate, in The ends of tightening bolt 3 are provided with slots, and the two ends of the stainless steel plate are welded in the slots to ensure sufficient welding strength. A connection hole is provided on the tie support plate, and the tie is clamped on the iron yoke of the iron core 8 by tightening bolts 3 arranged in the connection hole; a tie insulation 4 is set between the tie and the iron core. The diameters of the connection holes on the support plates of the high and low voltage side drawstrings are different, and an insulating sleeve 5 is provided on the side where the diameter of the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com