Energy efficiency combination evaluation method of machine tool product manufacture system

A technology for product manufacturing and combination evaluation, which is applied in manufacturing computing systems, instruments, data processing applications, etc., and can solve problems such as low average energy utilization of machine tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

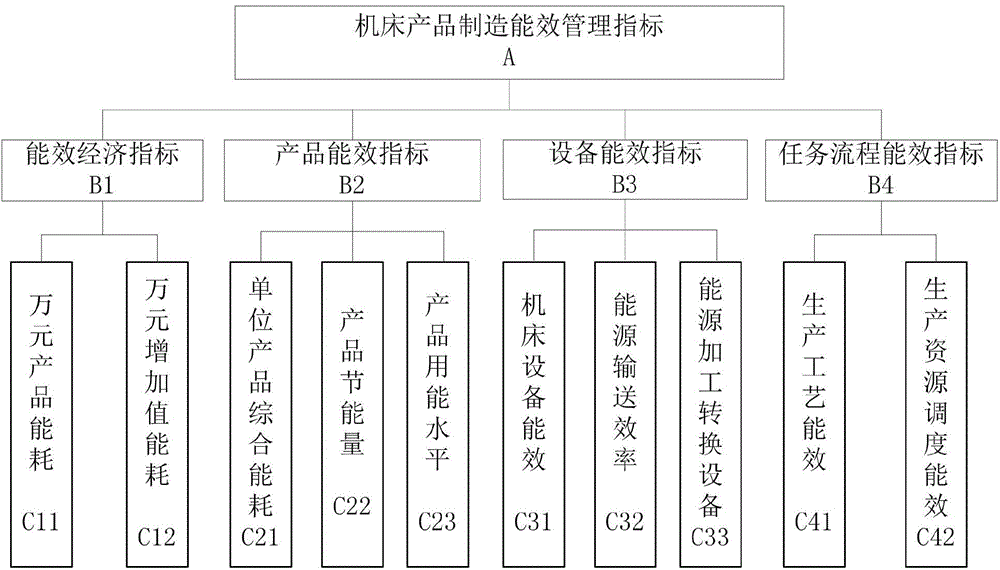

[0054] The energy efficiency combination evaluation method of the machine tool product manufacturing system designed by the present invention firstly conducts an inductive analysis on the constituent elements of the energy efficiency of the manufacturing system, establishes a comprehensive evaluation index system for the energy efficiency of the manufacturing system, then establishes a mathematical model for the evaluation of the energy efficiency of the manufacturing system, and finally uses the The combination of AHP, gray relational method and fuzzy comprehensive evaluation method is used to evaluate the energy efficiency of manufacturing system.

[0055] Such as figure 1 Shown, the present invention generally comprises the steps:

[0056] 1. Determine the weight constraints of different evaluation indicators for the energy effici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com