Motor temperature control test system based on peak clipping pulse wave modulation control

A pulse modulation and test system technology, applied in the direction of motor generator testing, etc., can solve the problem of unstable motor temperature detection, achieve low system cost, prevent misjudgment, and accurately control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

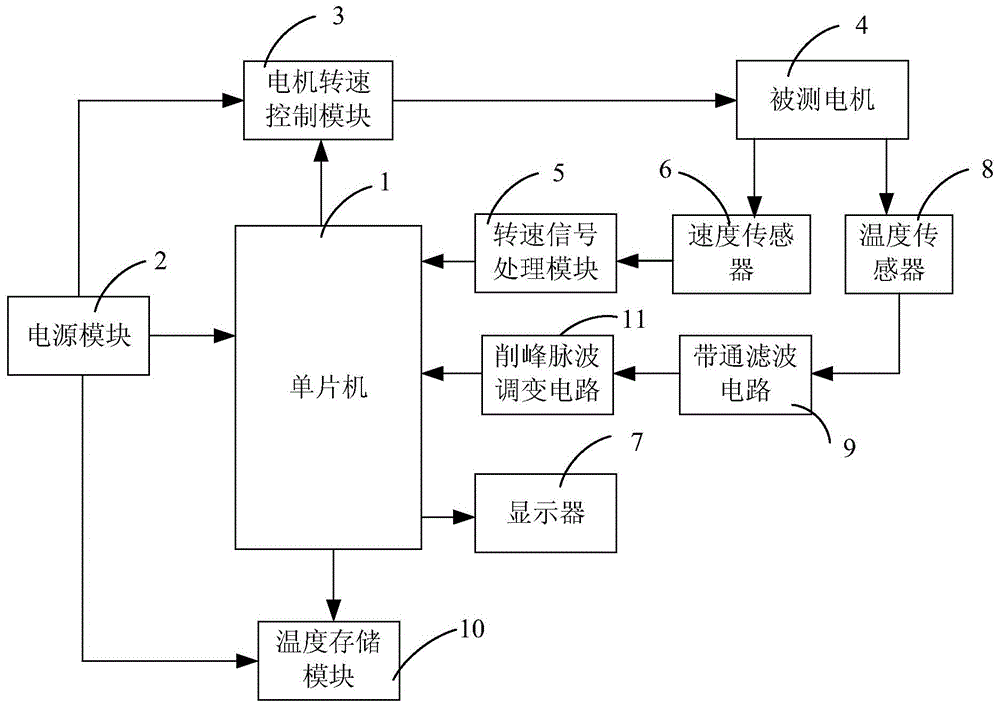

[0027] Such as figure 1 As shown, the present invention consists of a single-chip microcomputer 1, a power supply module 2 connected to the single-chip microcomputer 1, a motor speed control module 3, a speed signal processing module 5, a display 7, a temperature storage module 10, and a measured motor connected to the motor speed control module 3. Motor 4, a speed sensor 6 and a temperature sensor 8 connected to the motor 4 to be tested, a band-pass filter circuit 9 connected to the temperature sensor 8, the speed sensor 6 is also connected to the rotational speed signal processing module 5, and the power module 2 are also respectively connected with the motor speed control module 3 and the temperature storage module 10. In order to realize the purpose of the present invention, the present invention is also provided with a peak-shaving pulse modulation circuit 11 between the single-chip microcomputer 1 and the band-pass filter circuit 9.

[0028]Wherein, the single-chip micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com