Rapid Demolition Method of Expressway Arch Overpass by Controlled Blasting

A flyover and controlled blasting technology, which is applied in the field of construction and civil engineering, can solve the problems of temporarily closed traffic or long time for temporary rerouting, incomplete application of arched flyovers, and long construction time, etc., so as to save demolition time, The effect of short demolition time and reduced construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

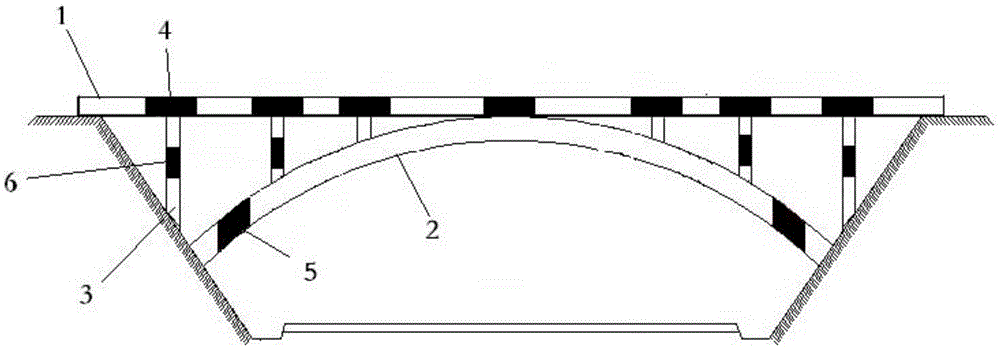

[0069] Aiming at the structural stress characteristics of the arch-type flyover bridge, the invention proposes a construction technique for safe and quick removal of the arch-type flyover bridge during expressway reconstruction and expansion, so as to ensure rapid recovery of road traffic.

[0070] Concretely, the rapid demolition method of the expressway arch type overpass by controlled blasting, such as Image 6 shown, including the following steps:

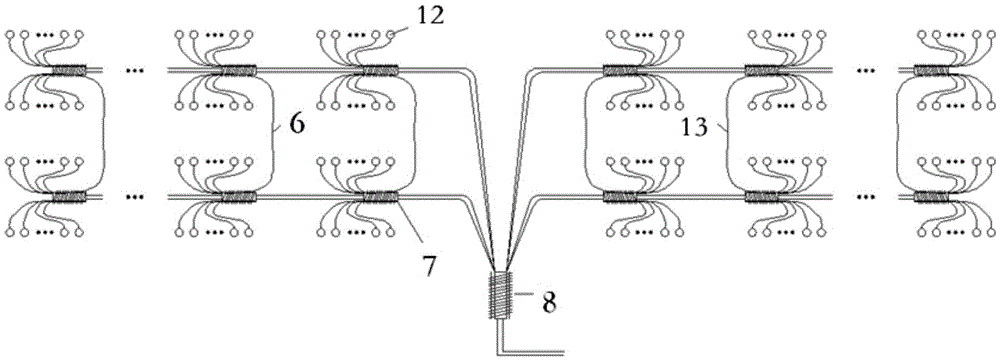

[0071] Step 1, design blasting construction scheme, including: design blasting parameters, design blasting network and design blasting safety protection measures;

[0072] In addition, it should be noted that since arch flyovers include arch flyovers without support connecting members and arch flyovers with support connecting members, so, for the category of arch flyovers, in When designing the blasting construction scheme, the parameters involved are slightly deviated, but the principles of the two are basically the same. Am...

Embodiment 2

[0123] Reconstruction and expansion project of Beijing-Hong Kong-Macao Expressway from Zhumadian to Xinyang section, K102+226 overhead arch bridge, bridge length 56.88m, bridge deck width 5m (including the width of both sides of the guardrail), net width 4m, bridge deck height 5.5m from the ground , the thickness of the bridge deck is 60cm, the thickness of the arch frame is 80cm, and the thickness of the longitudinal support wall is 30cm. The bridge was blasted using this plan on January 6, 2015. The specific process is as follows:

[0124] 1. Blasting design

[0125] (1) Design of blasting parameters

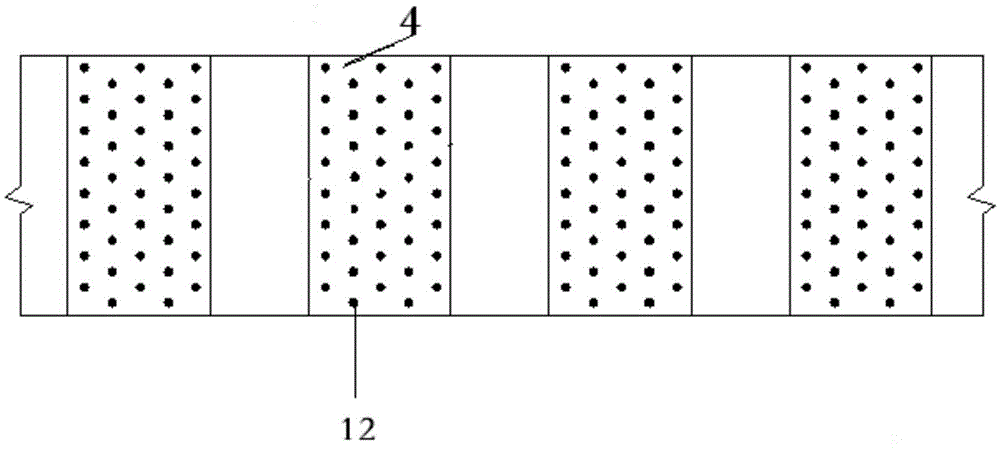

[0126] Blasting incisions: Drill and blast incisions at both ends of the arch near the arch surface of the abutment, the longitudinal support wall, and the bridge deck, so that the main body collapses downward after blasting. Among them, the longitudinal support blasting cut has two functions: on the one hand, it is used to destroy the supporting effect of the arch frame on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com