Thermoplastic elastomer composition with low TVOC and low Fogging for automotive trim and preparation method of thermoplastic elastomer composition

A thermoplastic elastomer and automotive interior technology, which is applied in the field of thermoplastic elastomer compositions and their preparation, can solve the problems of difficulty in detection, inability to enter automotive interior parts, and inability to meet usage requirements, and achieves simple processing and low specific gravity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

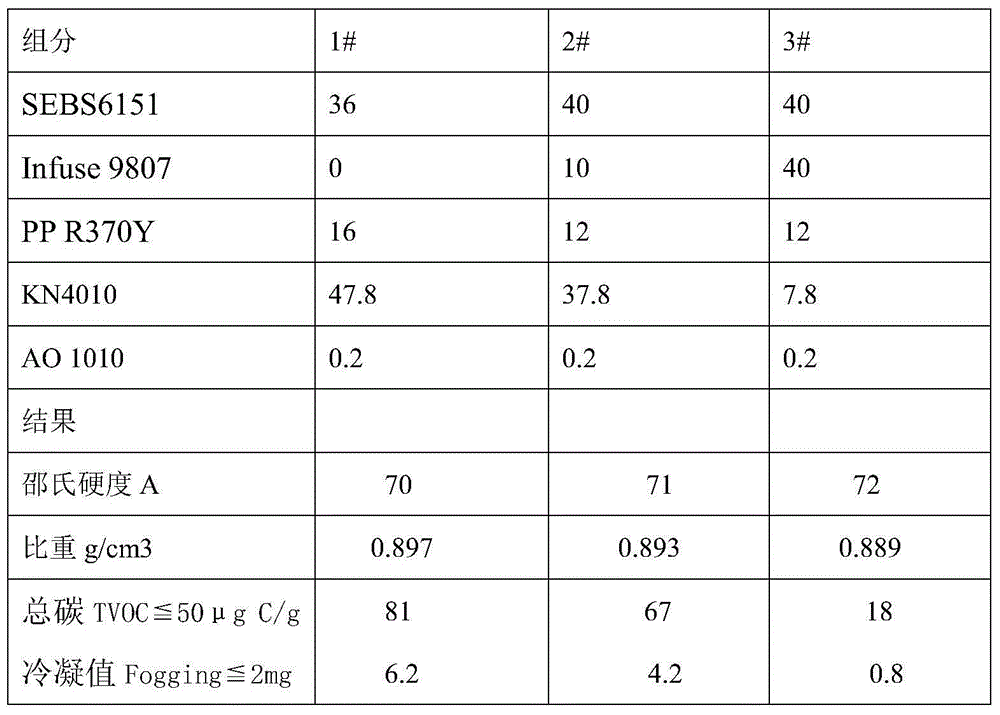

[0029] In Examples 1 to 4, the olefin block copolymer is produced by U.S. Dow Chemical Company under the trade name of Infuse9807; The styrene-ethylene-butylene-styrene block copolymer; the homopolypropylene is the homopolymer PP produced by SK Petrochemical Company in South Korea, and the product name is PP R370Y; the naphthenic oil is the naphthenic oil produced in Karamay, Xinjiang, and the commodity The name is KN4010; the antioxidant is a hindered phenolic antioxidant, specifically AO 1010 from Ciba.

[0030] Its preparation method is as follows:

[0031] (1) take raw materials by each component shown in Table 1 and the weight percentage content thereof;

[0032] (2) Mix SEBS and naphthenic oil (plasticizer) in the above raw materials in a high mixer for 20 to 30 minutes;

[0033] (3) Add other raw materials and mix evenly, take out;

[0034] (4) Then put it into a twin-screw machine to extrude and granulate, the host speed of the screw is 200-300 rpm, and the processi...

Embodiment 2

[0036] The raw materials used in embodiment 2 include styrene-ethylene-butylene-styrene block copolymer (SEBS6151) 40kg, naphthenic oil (KN4010) 5kg, olefin block copolymer (Infuse 9807) 39.9kg, homopolypropylene (PP R370Y) 15kg, antioxidant (AO 1010) 0.1kg.

Embodiment 3

[0037] The raw material that embodiment 3 adopts comprises styrene-ethylene-butylene-styrene block copolymer (SEBS6151) 30kg, naphthenic oil (KN4010) 15kg, olefin block copolymer (Infuse 9807) 45kg, homopolypropylene ( PP R370Y) 9.8kg, antioxidant (AO 1010) 0.2kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com