Improved structure of windshield wiper

A technology for wipers and wiper brackets, applied in the field of improved structure of wipers, can solve problems such as mismatching, product waste, scarcity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

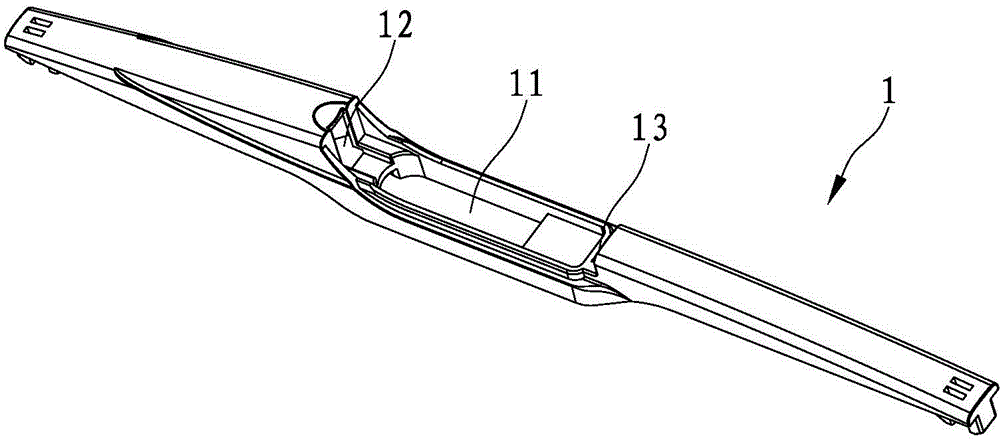

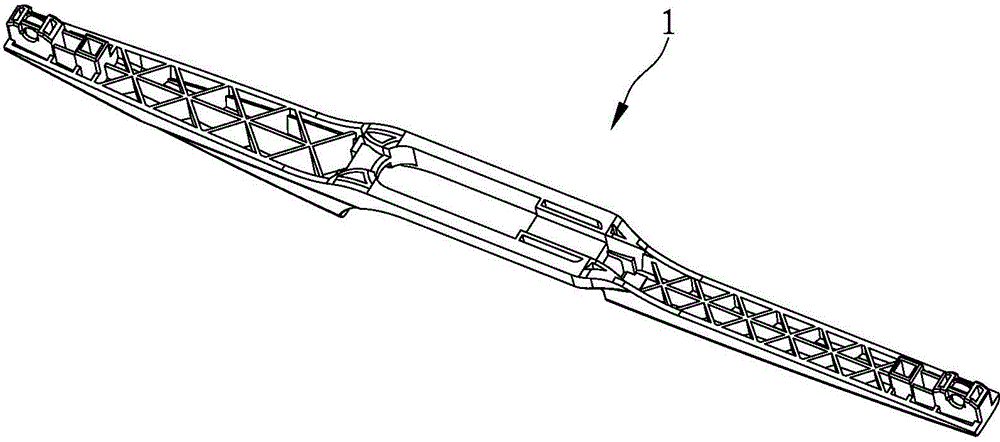

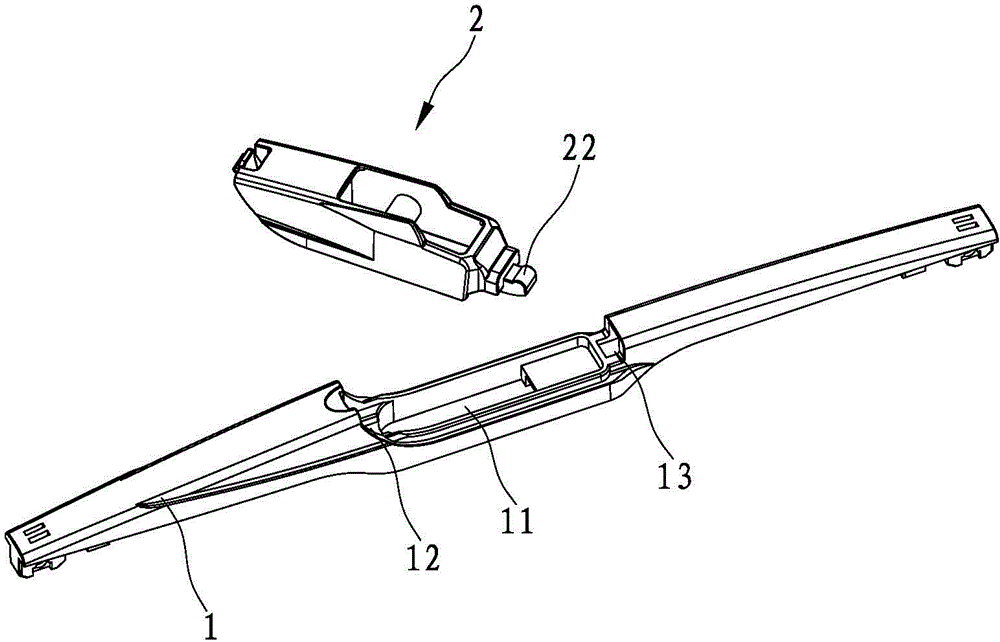

[0051] like figure 1 , figure 2 As shown, the structure of the wiper bracket 1 in all embodiments of the present invention is the same. The middle part of the wiper bracket 1 has an upper end and a fixing groove 11 open on both sides, and a front engaging groove is provided at both ends of the fixing groove 11 12 and rear clamping groove 13.

[0052] like Figure 3G , Figure 3H Shown is the first embodiment of the improved structure of a wiper according to the present invention, which includes a wiper bracket 1 , a connecting head 2 and a wiper arm 3 . The wiper arm 3 is installed on the wiper bracket 1 through the connector 2 .

[0053] like Figure 3A , Figure 3BAs shown, the front end of the connector 2 is provided with an elastic hook 21. The elastic hook 21 is a thin piece extending outward and upward from the front end of the connector. , the stepped surface 211 can be clamped on the inner top surface of the front clamping groove 12 of the fixing groove 11 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com