Reconsolidated bamboo floor carbonization apparatus

A carbonization device and recombined bamboo technology, which is applied in the field of bamboo product manufacturing, can solve the problems of poor carbonization effect and insufficient contact between bamboo fiber board and steam, and achieve the effects of simple structure, shortened carbonization time and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment the present invention is described in further detail:

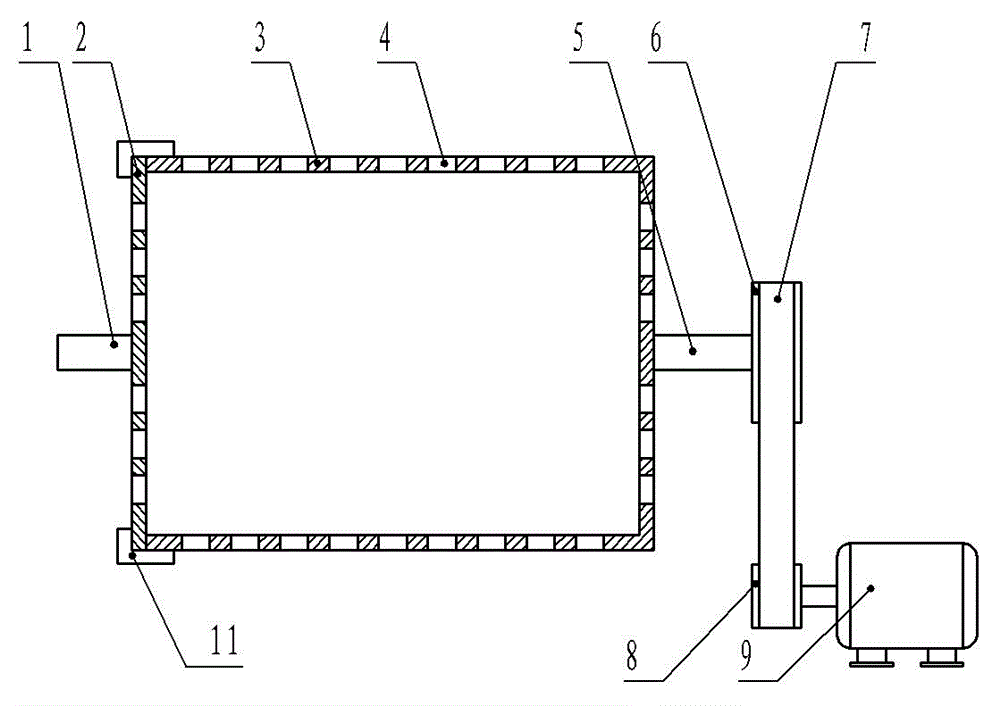

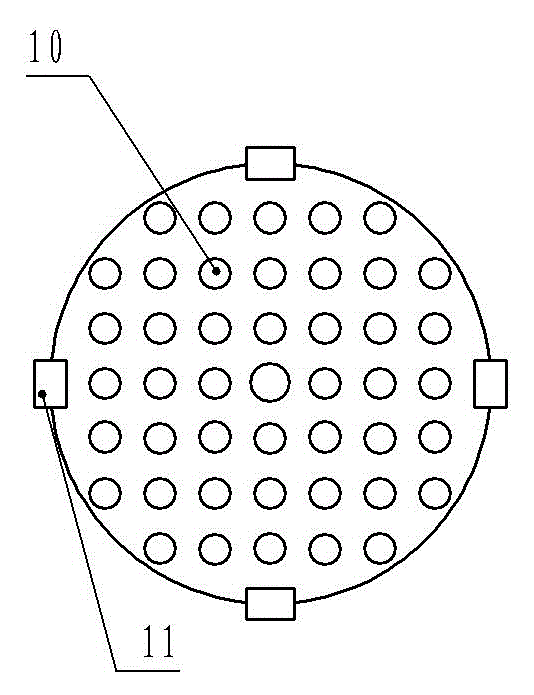

[0014] This recombined bamboo floor carbonization device includes a cylinder body 3 and a cylinder cover 2. The cylinder body 3 is a cylinder with one end open and the other end closed. A driving shaft 5 is provided, a driven pulley 6 is installed on the free end of the driving shaft 5, and a motor 9 is arranged at the bottom of the driven pulley 6, and a driving pulley 8 is installed at one end of the output shaft of the motor 9, between the driven pulley 6 and the driving pulley 8 A belt 7 is connected between them, and the cylinder cover 2 is closed with the opening end of the cylinder body 3 through a lock 11. The cylinder cover 2 is provided with a number of through holes 10, and a driven shaft 1 is installed in the middle of the outer side of the cylinder cover 2 to ensure that the cylinder body 3 rotates. Stable, the driven shaft 1 and the driving shaft 5 are horizontally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com