Special torque screwdriver connector for assembly of optical system

An optical system and special force technology, applied to screwdrivers, wrenches, wrenches, etc., can solve the problems of difficult to effectively control the pre-tightening force of the pressure ring, different tooling, etc., to achieve convenient processing of parts, reduce production costs and man-hours, and easy assembly solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

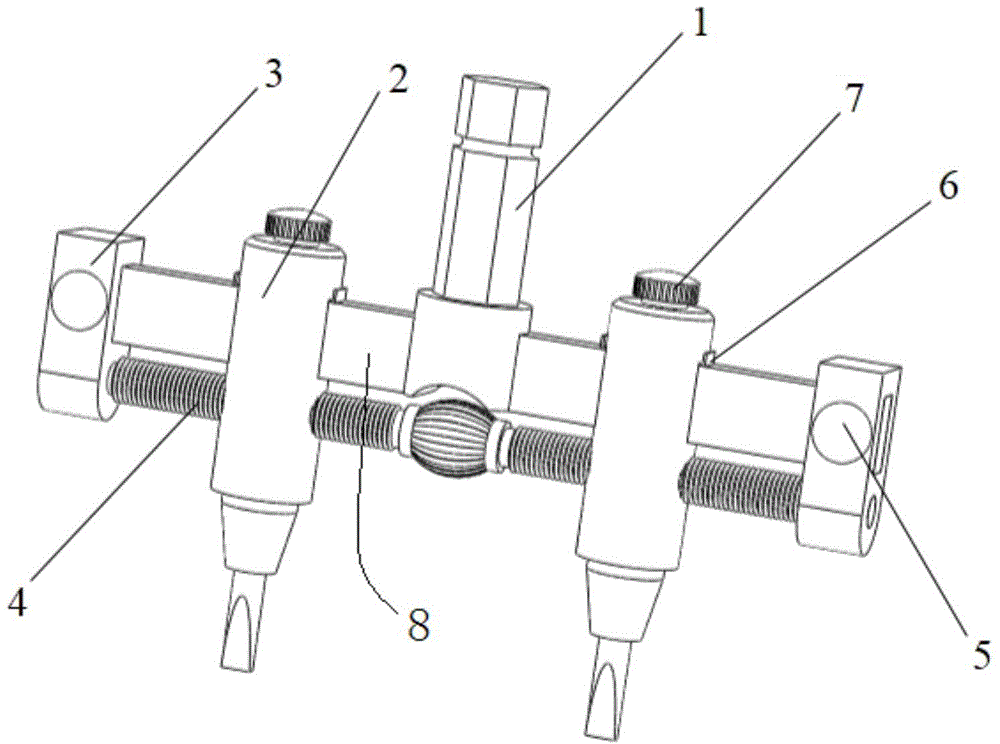

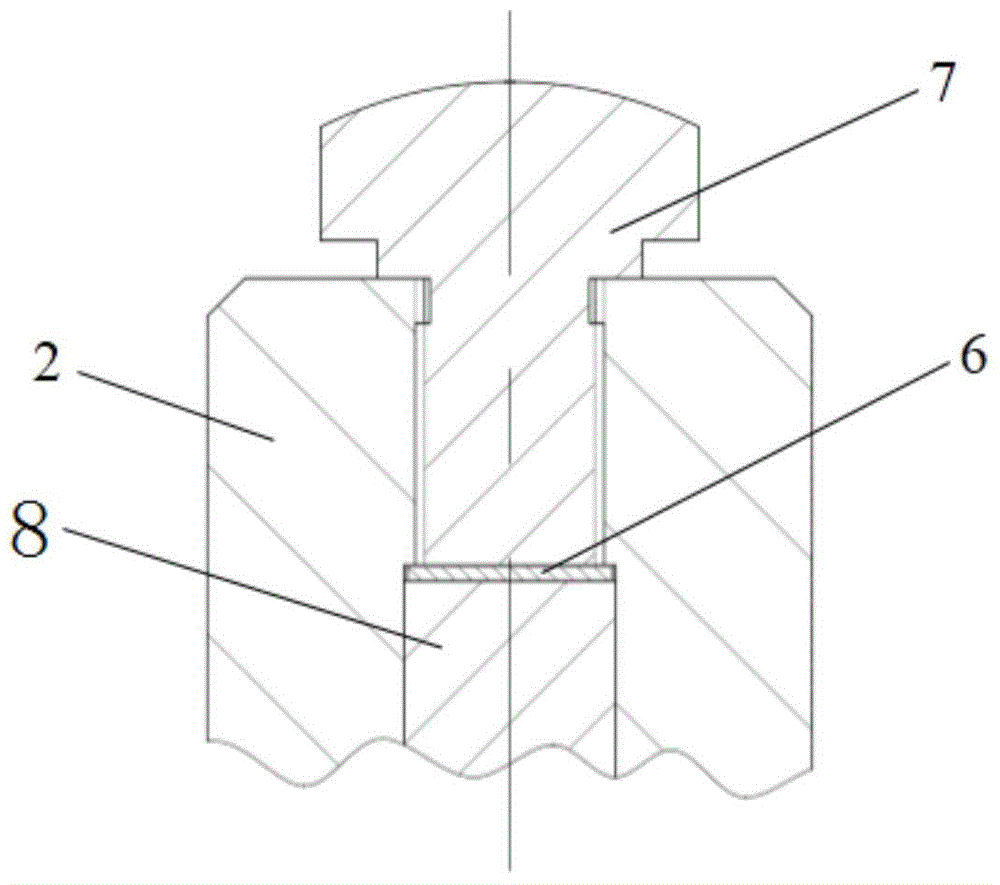

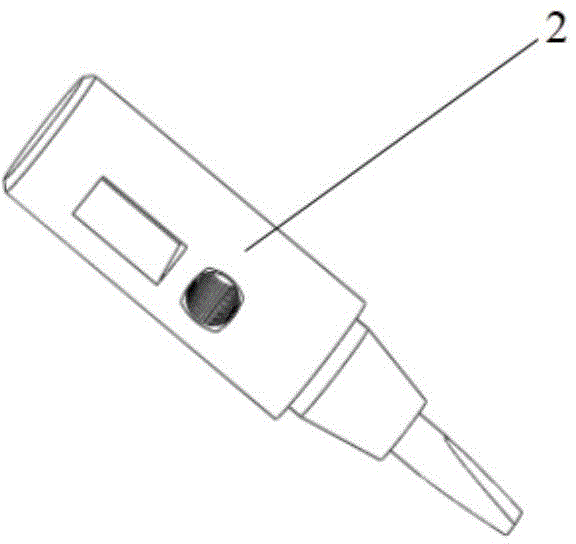

[0032] The invention provides a special torque screwdriver joint for optical system assembly, such as Figure 1 to Figure 6 , including a bracket, a two-way screw rod 4, a pressure ring claw head 2 and a limit block 3; the bracket includes a cross bar 8 and a two-way screw rod arranged parallel to the cross bar; the two-way screw rod is provided with a thread one and a thread two, and the thread one The pitch of the thread is the same as that of the second thread, but the direction is opposite; there are two clamping claws, and there are two holes on the clamping claws. Two holes, the two-way screw rod is threadedly connected with the pressure ring claw head, one of the pressure ring claw head is located at the first thread, and the other pressure ring claw head is located at the second thread position; there are two limit blocks, the cross bar and the two-way screw rod The two ends of each are respectively provided with the limit blocks, the cross bar and the limit block are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com