Automatic nut riveting device and automobile luggage carrier workpiece nut riveting method

A technology of automobile luggage rack and rivet nut, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as incompetence, low assembly efficiency and quality, and inability to guarantee product consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

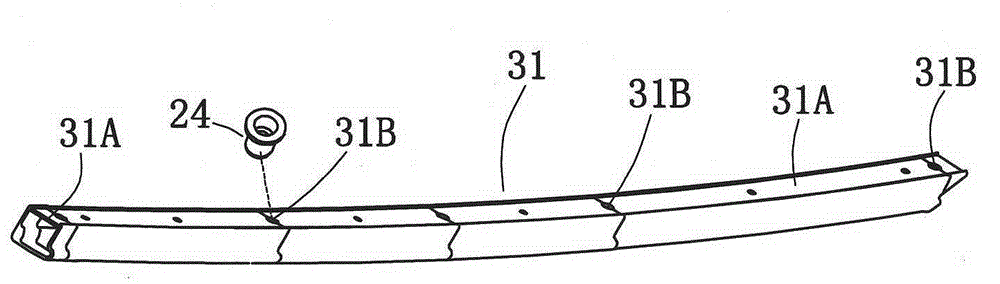

[0045] Such as Image 6 , Figure 7 As shown, the automatic rivet nut device of the present invention includes a first base frame 1, a first guide rail slider mechanism is arranged along the front and rear directions of the first base frame 1, and a first slide plate 3 is fixedly placed on the first slide block 2, and its two The first screw mandrel 5 is also arranged along the front and rear direction between the first linear guide rails 4, and the first screw mandrel 5 is driven by the first servo motor 6 at its rear end, and the first screw mandrel nut 7 is also fixed with the first slide plate 3 connection; the first slide plate 3 is provided with a fixed frame 8, the fixed frame 8 is provided with a rotating shaft sleeve 9, the rotating shaft in the rotating shaft sleeve 9 is driven by the second servo motor 10, the front end of the rotating shaft is fixedly connected to the rotating plate 11, along the rotating shaft Plate 11 is provided with the second guide rail slide...

Embodiment 2

[0057] In the second embodiment, a second workpiece resting frame 52 is added on the basis of the first embodiment. To further increase the degree of automation.

[0058] Such as Figure 12 As shown, in the front of the first workpiece resting frame 32, the second workpiece resting frame 52 for shelving a plurality of automobile luggage rack workpieces 31 and positioning is set, and the second workpiece resting frame 52 is arranged separately by the left side and the right side, each Each side includes a third underframe 53 and a shelving module 54 arranged on the third underframe 53 for shelving one end of a plurality of automobile luggage rack workpieces 31 and positioning. The shelving module 54 has a plurality of automobile luggage rack workpieces 31 to be placed on The pit 55 that shape, quantity match; The manipulator mechanism 56 that is used to move described automobile luggage rack workpiece 31 is set on the left side or the right side of second workpiece shelf 52, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com