Transformer maintenance decision method for optimizing reliability and economy

A decision-making method and technology for transformers, applied in switchgear, electrical components, etc., can solve the problems such as the key technology has not been broken through, the variation law and fluctuation range of online monitoring data and offline test data are different, and the cost is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

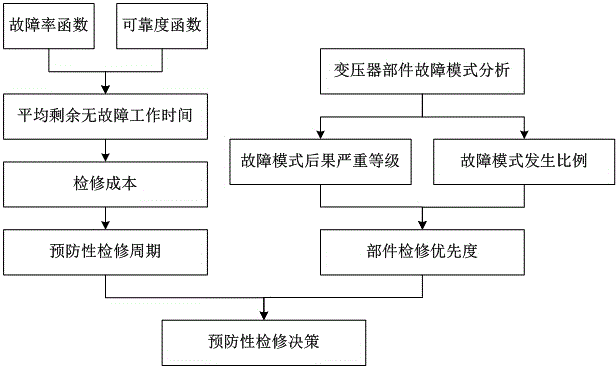

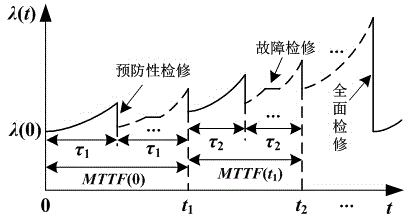

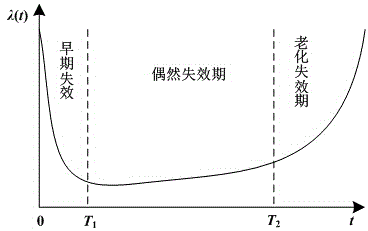

[0064] At present, the scheduled maintenance cycle of transformers is relatively fixed, and the equipment of the same type and capacity has the same cycle under various planned maintenances. The change of the reliability of the equipment itself with the operating years is not considered, and most of the research on the planned maintenance is in the equipment failure. Under the assumption that the rate is constant, the optimal arrangement of the maintenance period is carried out. Therefore, the present invention provides a transformer preventive maintenance strategy that comprehensively considers reliability and economy, uses Weibull function to describe the law of influence of aging on transformer failure rate, introduces service age regression factor to describe preventive maintenance effect, and establishes The transformer failure rate function and reliability function of preventive maintenance are considered. Taking the average remaining trouble-free working time as the max...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com