Graphene array surface plasma laser with real-time adjustable emitting wavelength

A graphene array, surface plasmon technology, applied in the field of optical communication, can solve the problem of loss of dynamic tuning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

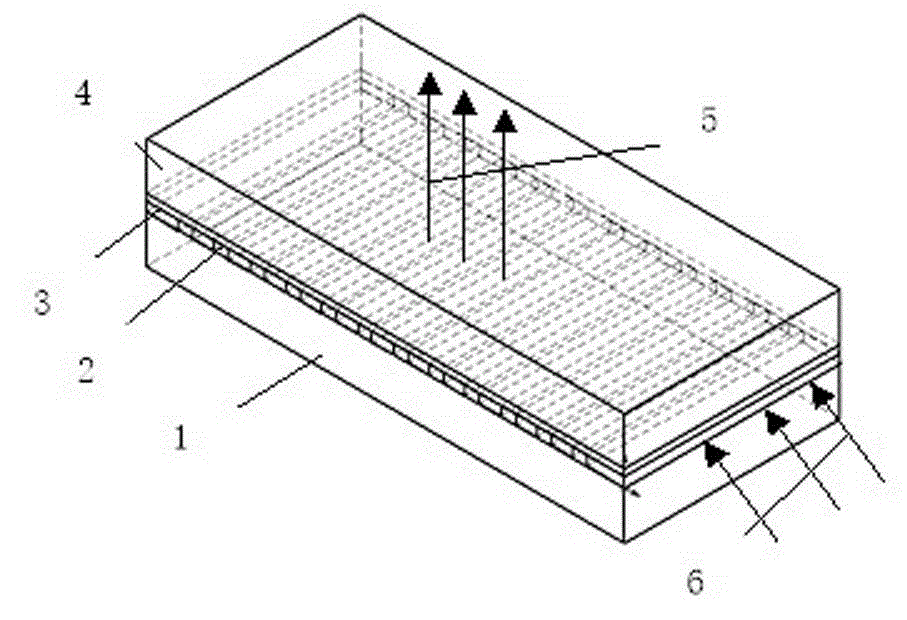

[0022] refer to figure 1 , a graphene array surface plasmon laser with real-time tunable emission wavelength, including sequentially stacked SiO 2 The base layer 1, the graphene periodic strip array layer 2, the organic solvent layer 3 and the glass layer 4, the graphene periodic strip array layer 2 is provided with a fluid channel connected with the microfluidic device. The length and width of each layer are 800nm and 600nm, SiO 2 The base layer 1 has a thickness of 100nm, the graphene periodic strip array layer 2 has a thickness of 30nm, the strip graphene period has a thickness of 20nm, the organic solvent layer 3 has a thickness of 30nm, and the glass layer 3 has a thickness of 150nm.

[0023] The graphene periodic strip array layer 2 is deposited on SiO 2 on base layer 1.

[0024] The organic solvent layer 3 is a dimethyl sulfoxide IR-140-DMSO mixed solution layer, and the organic solvent layer is sandwiched between the graphene periodic strip array layer 2 and the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com