A flushing structure of a heat exchanger

A technology of heat exchanger and filter structure, applied in the field of flushing structure of heat exchanger, can solve the problems of small contact area between steam and condenser, high production cost of aluminum alloy material, unfavorable steam condensation, etc., so as to improve heat exchange efficiency, The effect of reducing the failure repair rate and increasing the contact heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

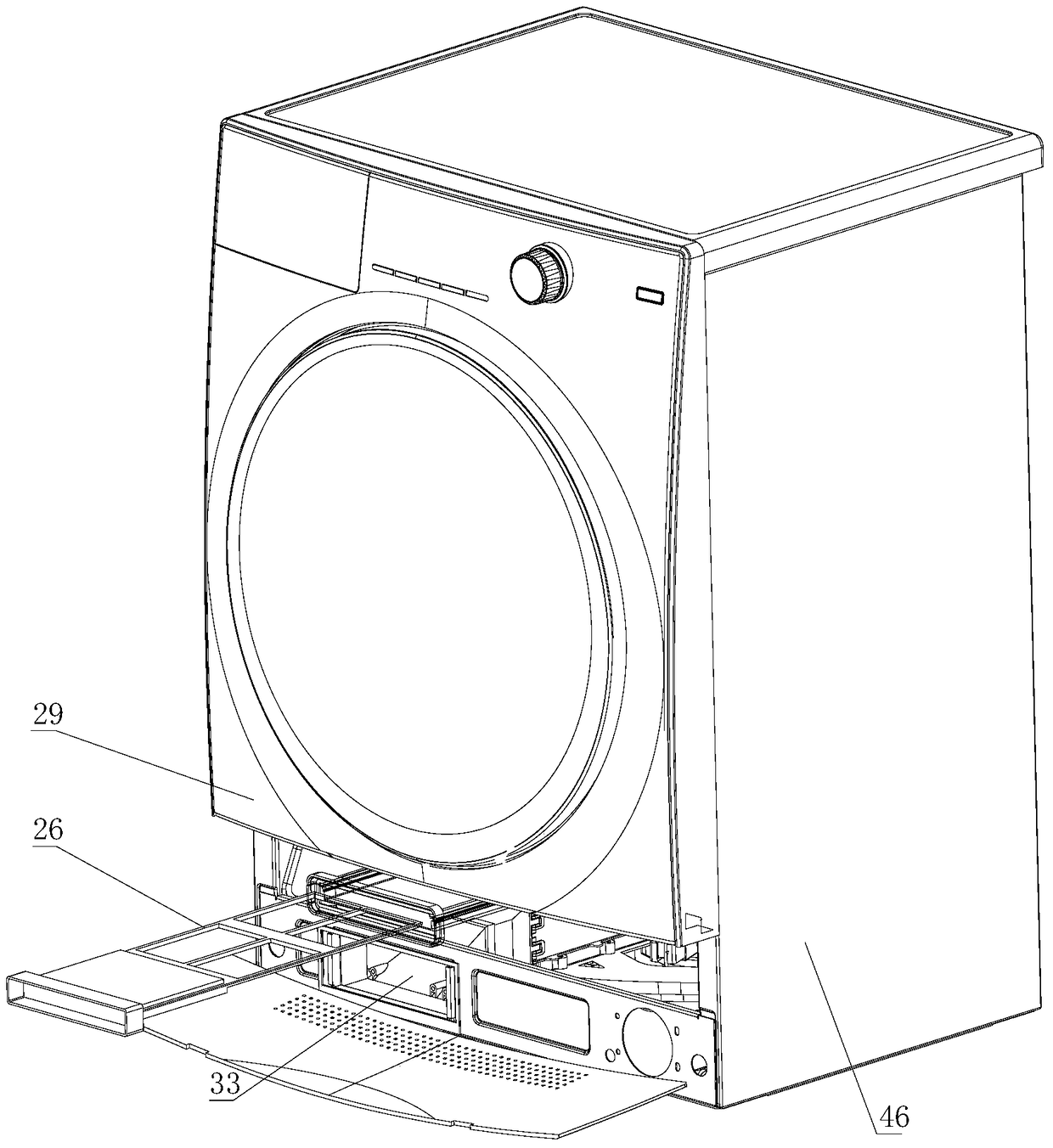

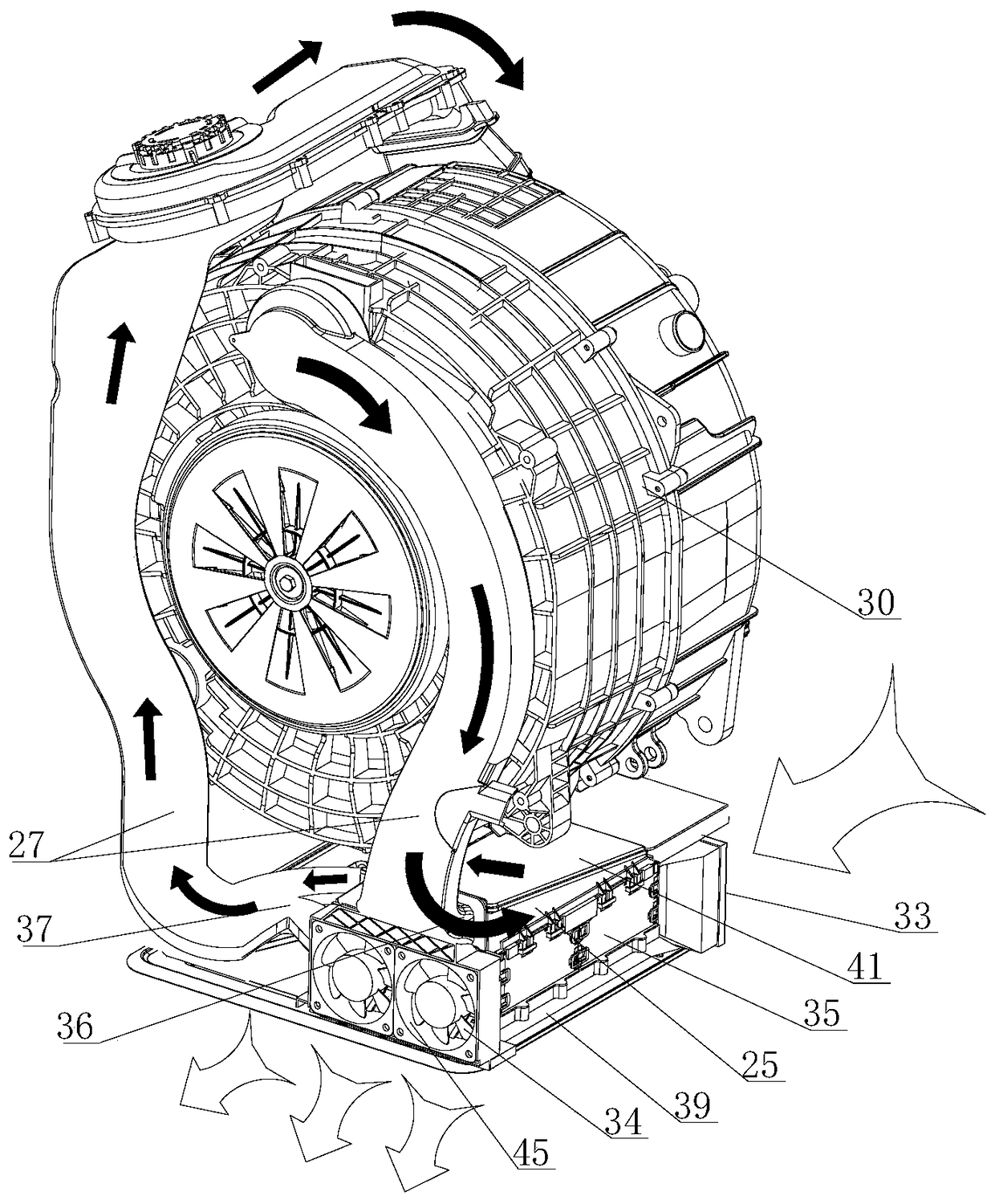

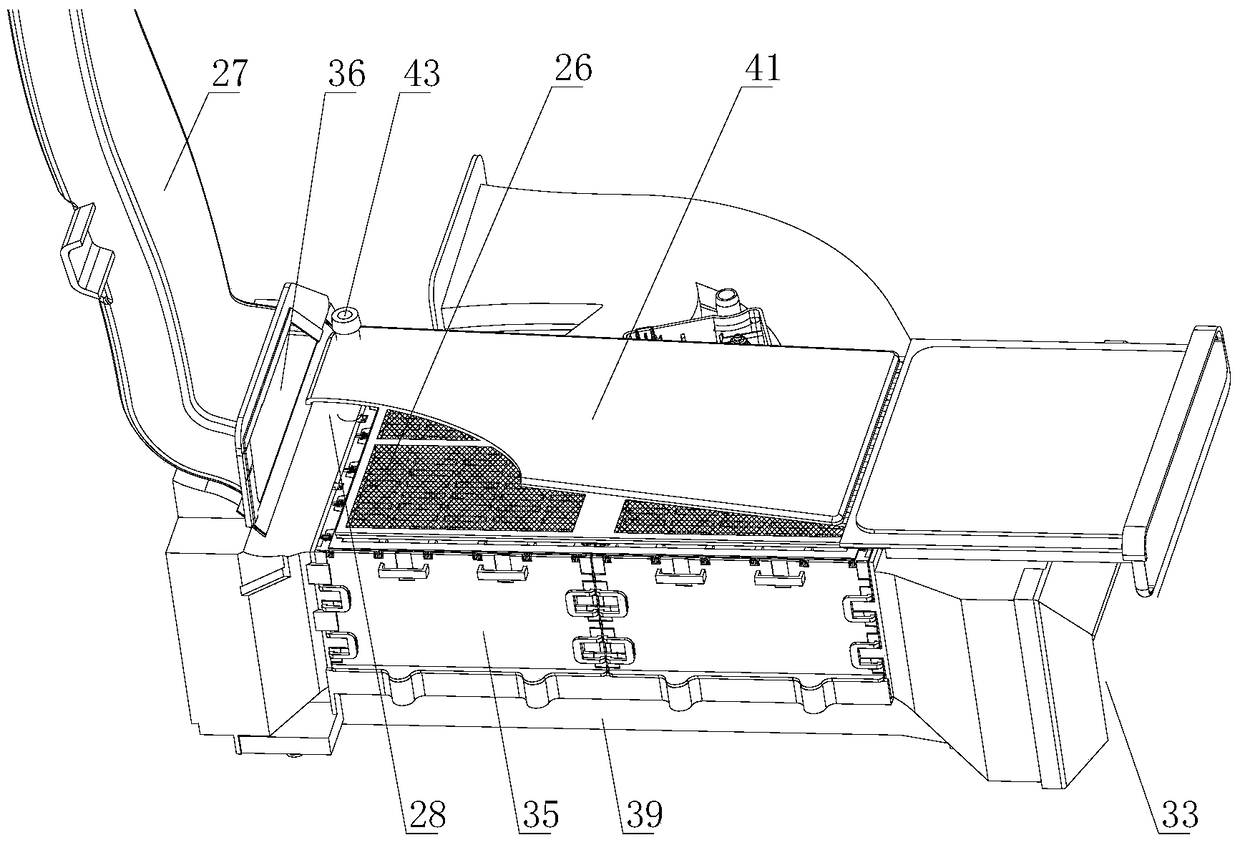

[0039] The flushing structure of the heat exchanger according to the present invention, the heat exchanger includes two sets of intersecting air passages, one set of air passages is connected with the hot air passage, and the other set of air passages is connected with the cold air passage. A flushing structure is arranged between the hot air inlet of the heat exchanger and the hot air path. It can wash away impurities such as lint attached to the hot air inlet 24 of the heat exchanger or the internal air path of the heat exchanger, so as to prevent the lint and other impurities from blocking the hot air inlet or the air path, and ensure the smooth flow of the air path.

[0040] like Figure 4 , Figure 13 , Figure 15 As shown, the flushing structure includes a spray layer 40 and a sealing cover 41, the spray layer 40 and the sealing cover 41 form a cavity, the spray layer 40 is provided with a plurality of spray holes 42, the sealing cover 41 is provided with a water inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com