Friction material composition and automobile braking friction material

A friction material and composition technology, applied in friction linings, chemical instruments and methods, and other chemical processes, etc., can solve problems such as insufficient strength of friction materials and insufficient stability of friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

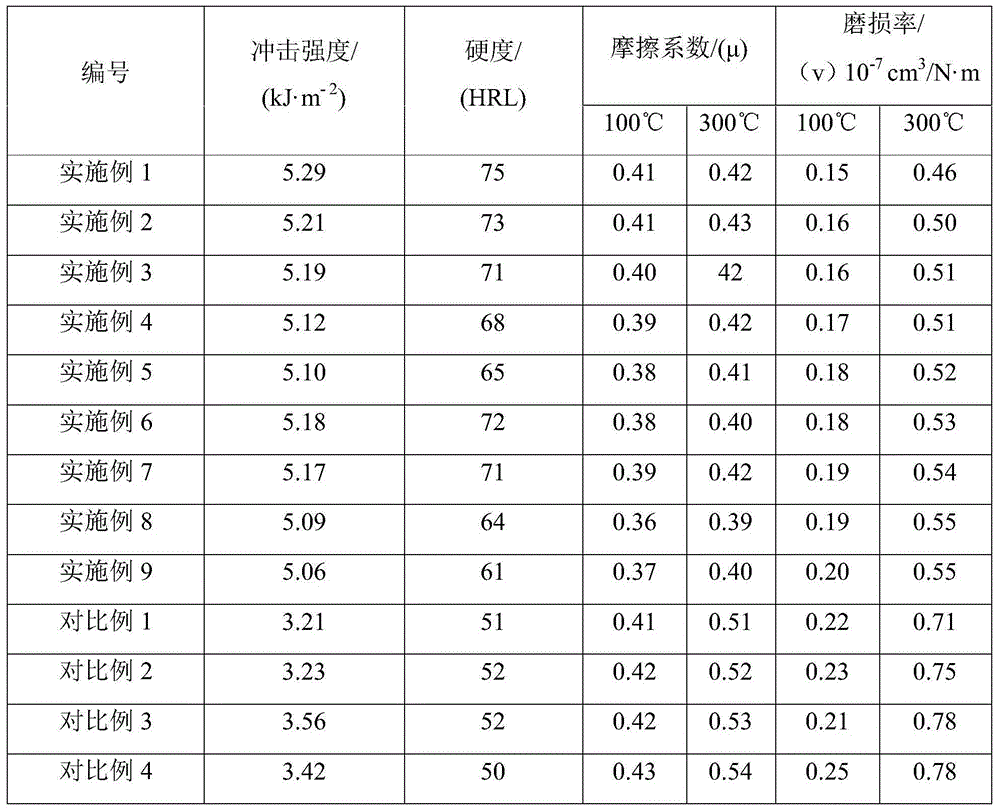

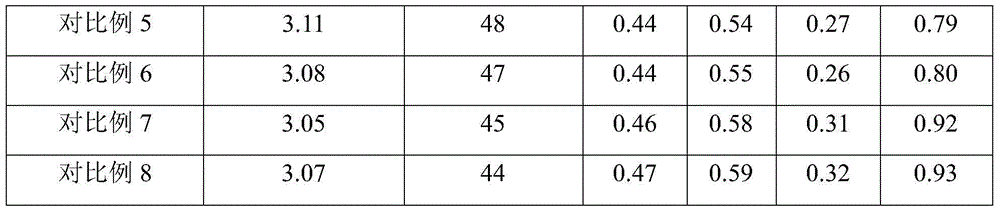

Examples

Embodiment 1

[0024] Reinforcing materials: glass fiber (average length 4mm, commercially available from Yancheng Guchi Glass Fiber Co., Ltd.), yellow paper fiber (average length 2.5mm, commercially available from Mujiang Weihua Perfume Factory, Shuangshui Town, Xinhui District, Jiangmen City), Gray paper fibers (average length 4mm, commercially available from Mujiang Weihua Perfume Factory, Shuangshui Town, Xinhui District, Jiangmen City) and ceramic fibers (average length 150mm, commercially available from Zichuan Jinyue Refractory Fiber Co., Ltd., Zibo City) were put into Rake type mixer (JF801SJ, Institute of Mechanical and Electrical Equipment, Geely University), mixing and stirring for 10 minutes, then resin modifier: nitrile rubber (commercially purchased from Hengshui Hanbangda Rubber and Plastic Trading Co., Ltd.) and cashew nut shell oil Powder (commercially purchased from Shanghai Longfa Chemical Co., Ltd.); binder: thermosetting phenolic resin (commercially purchased from Jining ...

Embodiment 2

[0027]The friction material composition and the friction material for automobile brake were prepared by the same method as in Example 1, except that, relative to 1 weight part of glass fiber, the content of the yellow paper fiber was 1.5 parts by weight, and the gray paper fiber The content of the ceramic fiber is 0.5 parts by weight, and the content of the ceramic fiber is 1.5 parts by weight.

Embodiment 3

[0029] The friction material composition and the friction material for automobile braking were prepared by the same method as in Example 1, except that, relative to 1 weight part of glass fiber, the content of the yellow paper fiber was 2.5 parts by weight, and the gray paper fiber The content of the ceramic fiber is 1 part by weight, and the content of the ceramic fiber is 1 part by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com