Externalinclined core pulling device of injection mold

An injection mold and oblique core-pulling technology, which is applied in the field of external oblique core-pulling devices, can solve the problems of high overall cost of the mold, occupying the internal space of the mold, and large mold shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

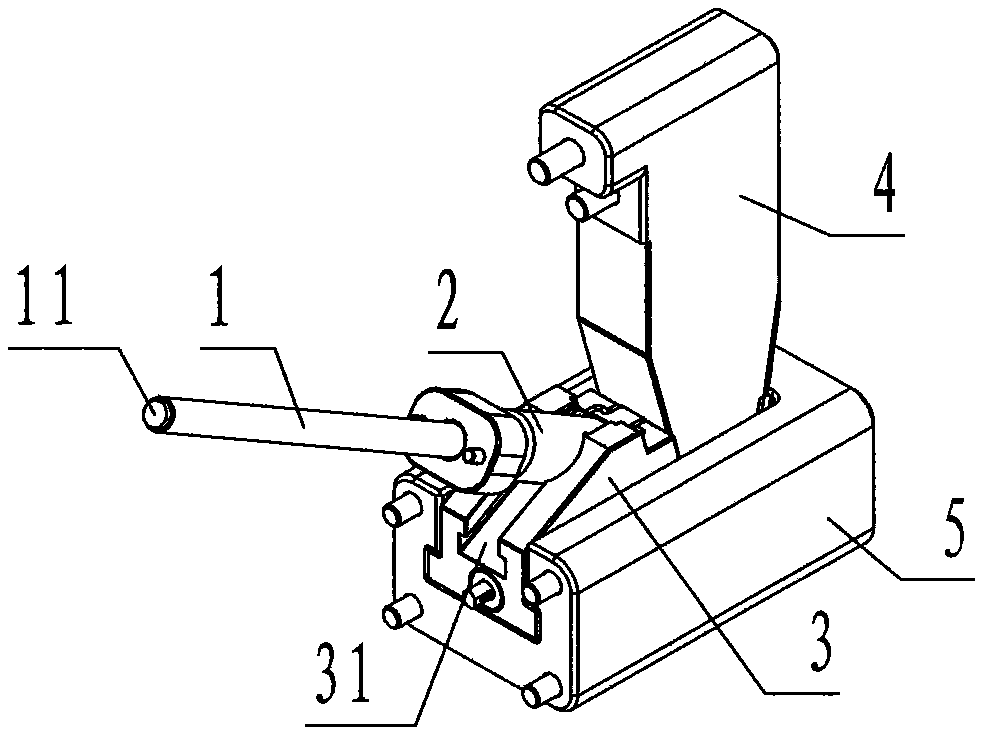

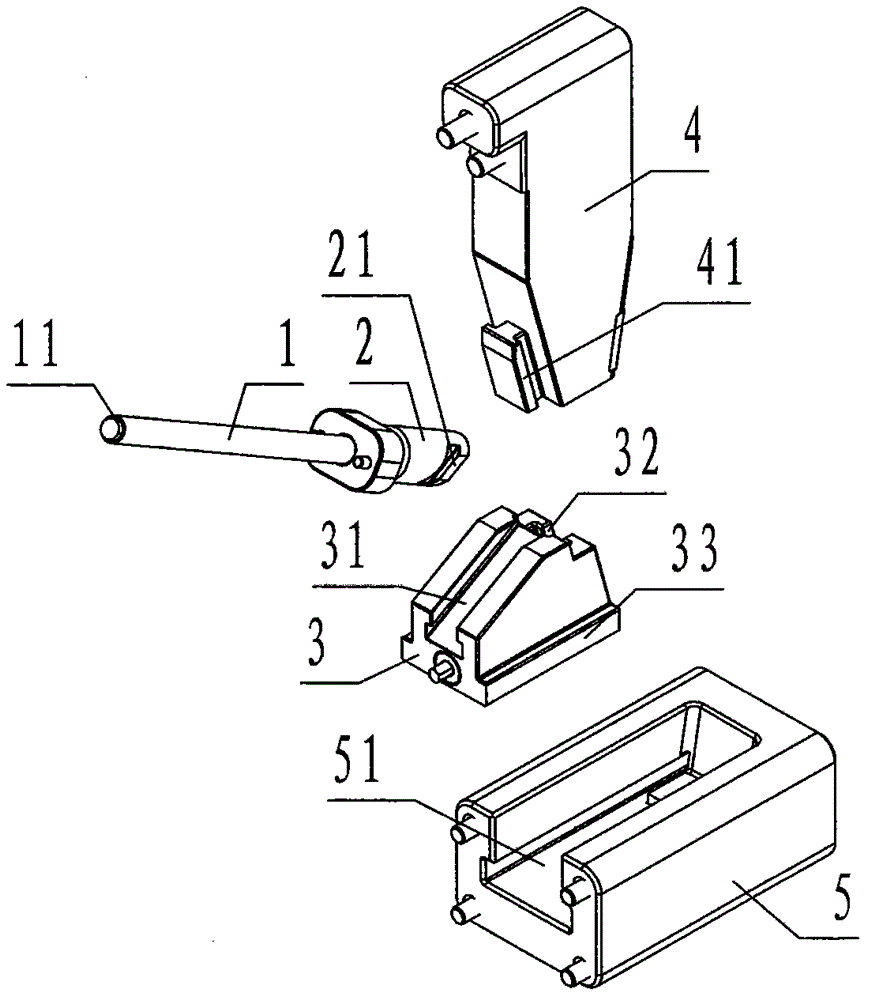

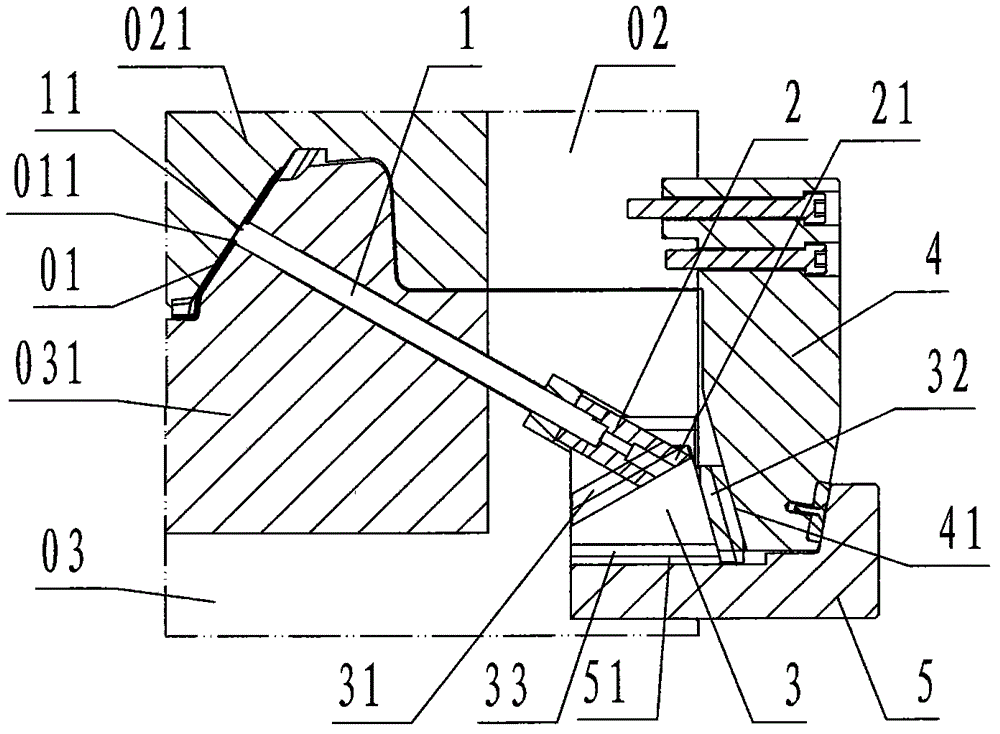

[0024] refer to Figure 1 ~ Figure 4 , an external oblique core-pulling device for an injection mold of the present invention, comprising an oblique core-pulling rod 1, an oblique sliding foot 2, a transverse slider 3, a longitudinal slider 4 and a sliding seat 5, wherein: the oblique core-pulling The core rod 1 is a cylindrical rod-shaped steel member, and the upper end of the oblique core rod 1 is provided with an oblique hole undercut 011 for forming the product 01. The sliding core is called the oblique hole core 11;

[0025] The inclined slide foot 2 is a cylindrical steel member, and the front and rear sides of the lower column wall of the inclined slide foot 2 are respectively provided with flanges inclined from left to right and whose cross section is rectangular, which are called inclined slide rails 21;

[0026] The horizontal slider 3 is a trapezoidal block-shaped steel member in the main view, and the left slope of the horizontal slider 3 is provided with a channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com