Expanding device

A technology of bottom plate and rotating disk, which is applied to the device and coating of the surface coating liquid, which can solve the problems of low glue coating efficiency and complicated operation, and achieve the effect of high spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

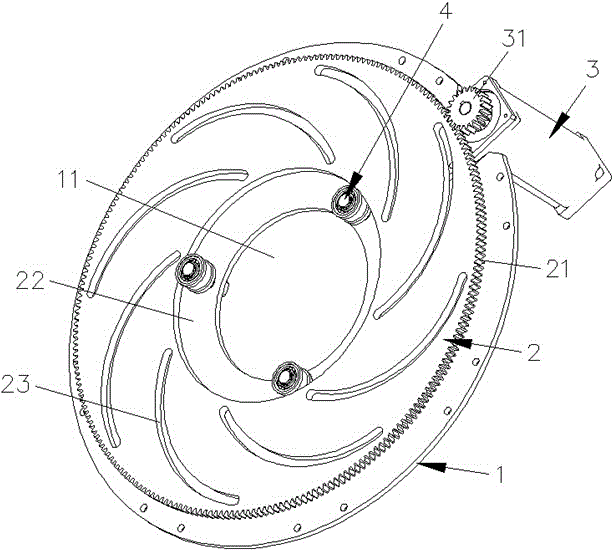

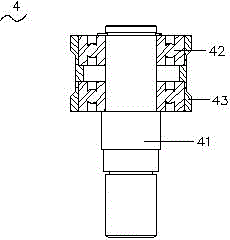

[0018] see figure 1 , The expanding device of the present invention includes a bottom plate 1, a rotating disk 2, a driving system 3, at least three guide wheel sets 4 and several chucks 5.

[0019] Please refer to figure 1 and figure 2 , the bottom plate 1 is provided with a bottom plate through hole 11 . In this embodiment, the bottom plate 1 is in the shape of a circular plate, and the through holes 11 in the bottom plate are in the shape of round holes.

[0020] The rotating disk 2 is arranged parallelly above the bottom plate 1, the outer periphery of the rotating disk 2 is provided with a rotating gear 21, and the center of the rotating disk 2 is provided with a central hole 22 of the rotating disk, and the central hole 22 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com