An industrial waste gas treatment system

A technology for treating system and industrial waste gas, which is applied in the direction of air quality improvement, use of liquid separation agent, separation of dispersed particles, etc., which can solve the problems of difficult control of reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

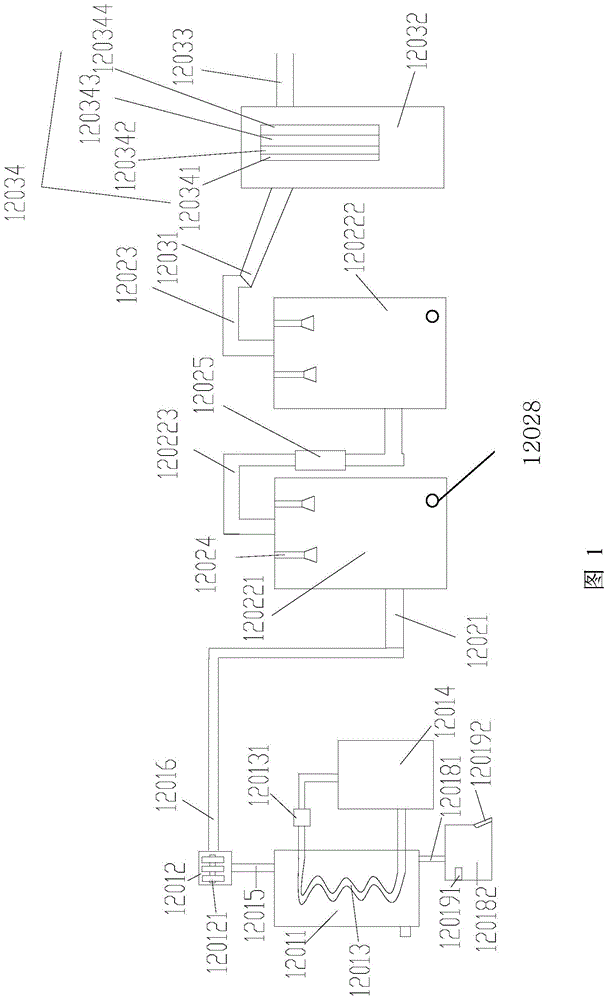

[0023] like figure 1 As shown, this embodiment includes a high-temperature exhaust gas treatment device, a spray purification exhaust gas device, and a deodorizing device from front to back.

[0024] The high-temperature exhaust gas treatment device includes a ventilation tank 12011 , a second tube condenser 12012 , a coil pipe 12013 and a refrigeration system 12014 . The lower end of the ventilation tank 12011 is provided with an air inlet, the coil 12013 is spirally arranged in the inner cavity of the ventilation tank 12011, the bottom of the coil 12013 is provided with a water inlet, and the coil 12013 is provided with a water inlet. The top of 12013 is provided with a water outlet, and both the water inlet of the coiled pipe 12013 and the water outlet of the coiled pipe 12013 extend to the outside of the vent tank 12011. The water inlet of the coil 12013 is connected with the water outlet of the refrigeration system 12014 , and the water outlet of the coil 12013 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com