A shaping mechanism of a round steamed bun machine

A round steamed bun and shaping wheel technology, applied in the field of food machinery, can solve the problems of unsightly appearance, inaccurate control of dough size, irregular shape of round steamed buns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

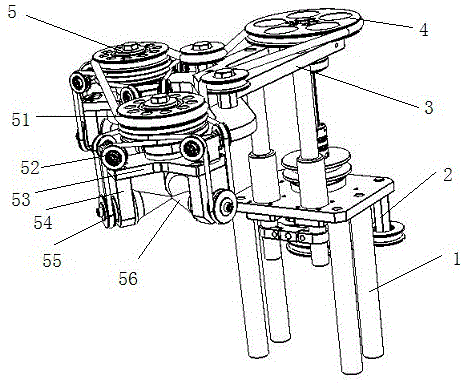

[0008] The specific embodiments of the present invention will now be further described in conjunction with the accompanying drawings, such as figure 1 , in this example, the structure of the lower bracket 1 is a combination of a column and a platform, the column is installed on the work surface of the frame of the steamed bun machine, and the upper end of the column is fixed to install the platform; the lower transmission device 2 adopts a chain drive combined with a cam drive. The transmission provides power for the transmission wheel of the upper transmission, and the cam drive controls the up and down movement of the upper bracket 3 on the lower bracket 1; a guide sleeve is installed on the platform of the lower bracket 1. In this example, two guide sleeves are used, and a transmission shaft seat is set at the same time. The spline shaft is installed in the transmission shaft seat to connect with the transmission wheel of the upper transmission device 4; the upper bracket 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com