Core holder

A core holder and core technology, applied in the field of oil and gas exploration and development, can solve problems such as affecting the stability of experimental results, failing to meet the requirements of the temperature and pressure test experiments for simulating tight oil reservoirs, and drifting the resonance frequency. It is beneficial to oil and gas exploration and development, meets the requirements of test experiments, and is easy to load and unload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

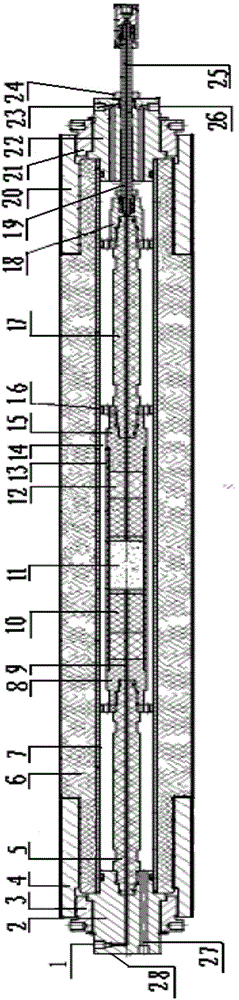

[0036] like figure 1 A specific embodiment of the core holder of the present invention is shown. In this embodiment, the core holder includes a cylinder body 6 made of glass fiber reinforced plastic material, a core assembly set in the cylinder body 6, left and right mandrel end seat assemblies connected to both ends of the core assembly, and a cylinder body 6 The left and right connecting sleeves 4 and 20 are in sealing connection with the left and right mandrel end seat assemblies. Moreover, the cylinder body 6 , the rock core assembly and the left and right mandrel end seat assemblies together form the annular pressure chamber 14 in the cylinder body 6 . The annular pressure chamber 14 bears the annular pressure applied to the core 11 . In addition, the left and right ends of the barrel 6 are stepped structures, and external threads are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com