Slim borehole wall corer

A coring and wellbore technology, which is used in the extraction of undisturbed core devices, earthwork drilling, etc., to ensure the acquisition rate of the coring device, avoid contact, and ensure the harvest rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

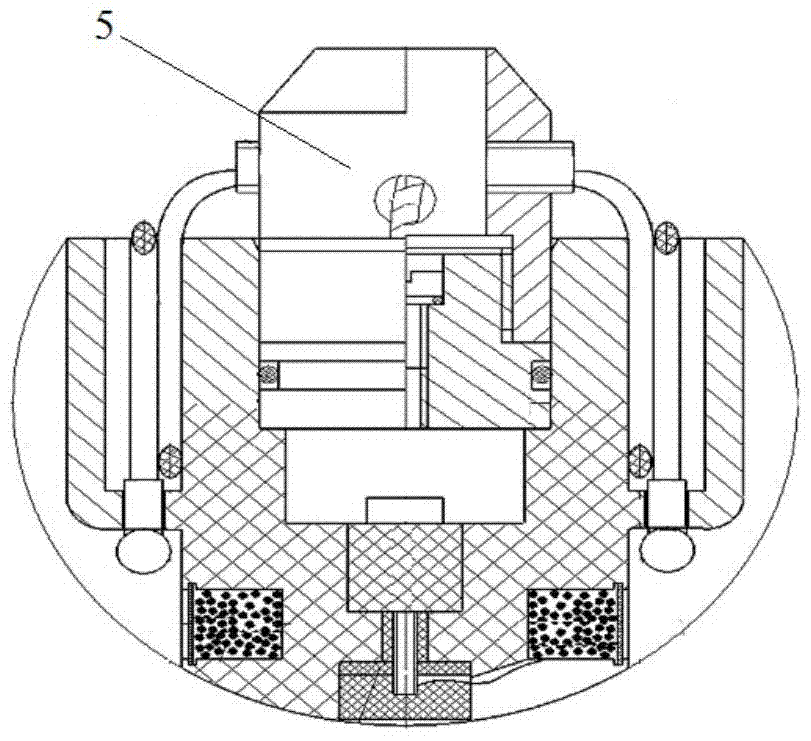

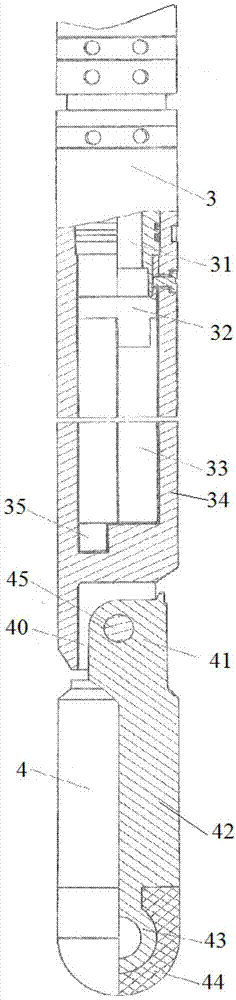

[0029] At present, there is no special sidewall coring device for wells smaller than 6 inches. Using the existing drilling coring, the process is cumbersome, long time, labor-intensive, and high cost; using the existing sidewall coring device, the coring barrel is exposed , poor safety performance; and for irregular wells or inclined wells, when using a coring device with an additional guiding rubber cone, it is easy to generate vibrations, destroy the stability of the electronic circuit, and easily break down. The invention provides a A slimhole borehole wall coring device capable of solving the above-mentioned problems.

[0030] The slimhole sidewall coring device includes a rotary sub, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com