A kind of ecological composite board and its manufacturing method

A composite panel and ecological technology, applied in chemical instruments and methods, synthetic resin layered products, covering/lining, etc., can solve the problems of poor environmental performance and stability, unattractive shape, high production cost, etc., and achieve good sound insulation effect, The effect of soft and smooth surface and high impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

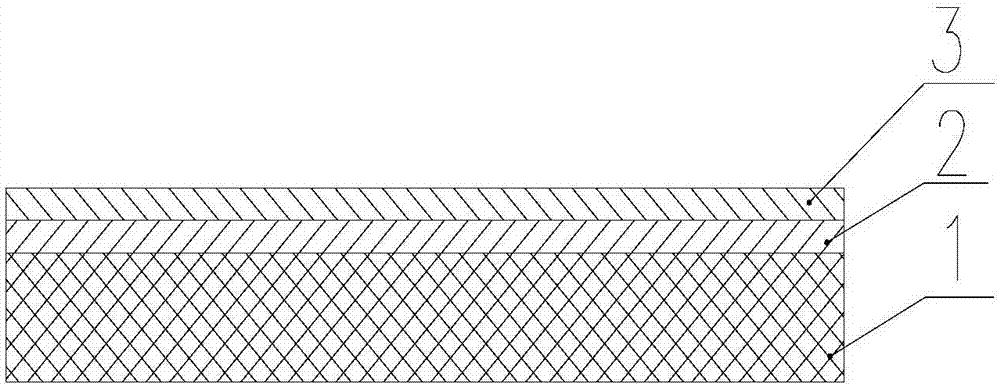

[0040] A kind of ecological composite board that the present invention proposes, such as figure 1 As shown, it includes a surface acrylic board layer 3, a middle loofah layer 2 and a bottom density board layer 3, and the loofah layer, the density board layer and the acrylic board layer are respectively fixed by an adhesive layer, and the surface acrylic board layer adopts Transparent acrylic sheet.

[0041] The transparent acrylic board has high hardness and strength, is easy to clean, is resistant to scrubbing, and has a smooth surface. At the same time, the purpose of using transparency is to reveal the texture of the natural loofah, which has a three-dimensional effect and reflects the beauty of natural ecological harmony. The bottom density board layer is bonded with a formaldehyde-free adhesive, and the choice of 18mm thick density board as the bottom layer can a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com