A kind of preparation method of light-emitting diode that improves leakage current

A technology of light-emitting diodes and leakage current, applied in circuits, electrical components, coatings, etc., can solve problems such as crystal growth defects, adverse effects on the performance or function of the latter layer, reverse leakage of light-emitting diode structures, etc., to increase the carrier gas. flow, improve reliability, and reduce the effect of reverse leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

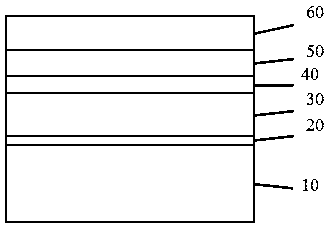

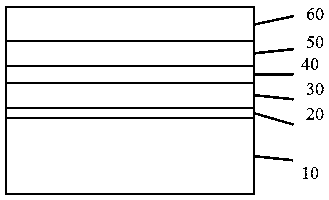

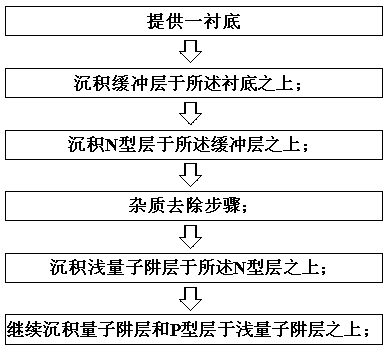

[0031] See attached figure 2 and 3 , a light-emitting diode preparation method for improving leakage current, comprising the following processes:

[0032] First provide the substrate 10, put it into the MOCVD chamber, the material of the substrate 10 is sapphire, silicon, silicon carbide, etc., the sapphire substrate is preferred here; adjust the temperature of the MOCVD chamber to 400~1200°C, and feed the metal source (gallium source is preferred here), NH 3 、H 2 Perform epitaxial growth of a buffer layer 20 with a thickness of 10-3000 nm, and cover the surface of the substrate 10; adjust the temperature of the chamber to 900-1200 ° C, in the above metal source, NH 3 、H 2 Under the condition of continuous feeding, increase the feeding of N-type impurities to grow the N-type layer 30 with a thickness of 4-6 μm. The impurities are selected from one of silicon, germanium or tin. In this embodiment, silicon impurities are preferred. , the impurity concentration is 1×10 17 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com