Similar material for simulating expansible tunnel surrounding rock and preparation method of similar material

A technology similar to materials and tunnels, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of mechanical properties and deformation characteristics change, damage, high cost of remote sampling, etc., to improve permeability, Suppresses swelling and enhances cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The concrete steps of described similar material preparation are as follows:

[0036] (1) Select expansive soil and fly ash without obvious impurities and larger consolidated lumps;

[0037] (2) Determine the permeability of similar materials required by the model test, and configure different proportions for comparative experiments;

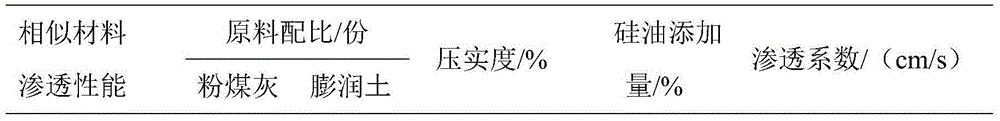

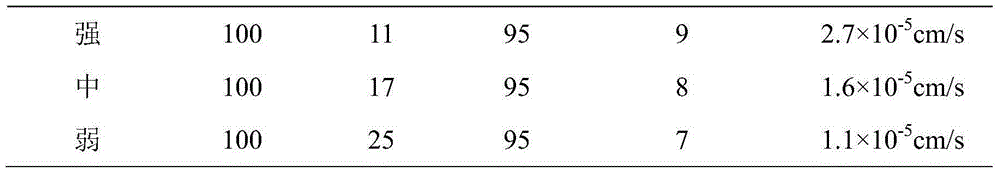

[0038] (3) proportioning by weight: 100 parts of fly ash and 11 parts of bentonite;

[0039] (4) Feeding and stirring, so that the materials are mixed evenly;

[0040] (5) Add silicone oil to the uniformly stirred material, the quality of silicone oil is 9% of the sum of fly ash and bentonite quality;

[0041] (6) Control the degree of compaction according to the needs of the experiment to make the model test material compacted and formed. Under the condition of 95% degree of compaction, the permeability coefficient is 2.7×10 -5 cm / s.

Embodiment 2

[0043] The concrete steps of described similar material preparation are as follows:

[0044] (1) Select expansive soil and fly ash without obvious impurities and larger consolidated lumps;

[0045] (2) Determine the permeability of similar materials required by the model test, and configure different proportions for comparative experiments;

[0046] (3) 100 parts of proportioning fly ash and 17 parts of bentonite are carried out by weight;

[0047] (4) Feeding and stirring, so that the materials are mixed evenly;

[0048] (5) Add silicone oil to the uniformly stirred material, and the quality is 8% of the sum of fly ash and bentonite quality;

[0049] (6) Control the degree of compaction according to the needs of the experiment so that the model test material is compacted and formed. In the case of 95% degree of compaction, the permeability coefficients are 1.6×10 -5 cm / s.

Embodiment 3

[0051] The concrete steps of described similar material preparation are as follows:

[0052] (1) Select expansive soil and fly ash without obvious impurities and larger consolidated lumps;

[0053] (2) Determine the permeability of similar materials required by the model test, and configure different proportions for comparative experiments;

[0054] (3) 100 parts of proportioning fly ash and 25 parts of bentonite are carried out by weight;

[0055] (4) Feeding and stirring, so that the materials are mixed evenly;

[0056] (5) Add silicone oil to the uniformly stirred material, and the quality is 7% of the sum of fly ash and bentonite quality;

[0057] (6) Control the degree of compaction according to the needs of the experiment so that the model test material is compacted and formed. In the case of 95% degree of compaction, the permeability coefficients are 1.1×10 -5 cm / s.

[0058] Table 1 The ingredient composition and permeability of the three examples meet the permeabi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability coefficient | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com